Regarding cantilever cranes, everyone may be a little unfamiliar. Cantilever Crane factory operators must strictly abide by the operating rules before they can operate the cantilever crane independently, and should follow the safety rules. Here is a brief introduction to the main points of maintenance, adjustment and design of cantilever cranes.

1. Maintenance and adjustment of cantilever crane:

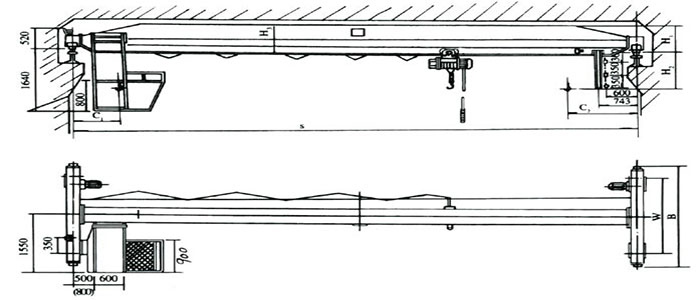

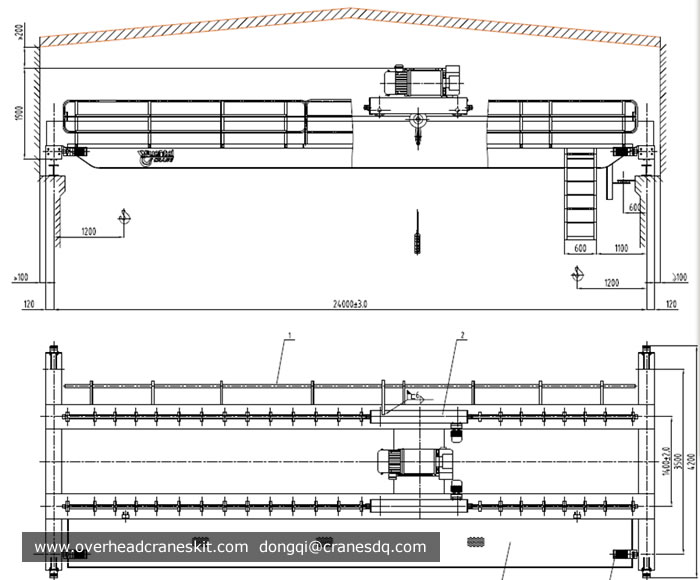

1. Inspection and adjustment of metal structure In order to ensure the normal use of cantilever cranes and extend the service life of parts, components and cantilever cranes, end beam cantilever cranes must be checked and adjusted frequently.

The inspection content of the metal structure and the judgment standard The metal structure of the cantilever crane is inspected 1 to 2 times a year, focusing on the loosening and falling of connecting bolts and nuts, cracks and cracks in structural materials and welds, bridge deformation, corrosion of structural parts, etc. content.

For the inspection items and contents of the cantilever crane and trolley operating mechanism, refer to the motor operation and maintenance manual and the hoist operation and maintenance manual.

2. Maintenance of electrical equipment Regular maintenance and frequent inspections are important measures for the maintenance of electrical equipment and should be done in accordance with regulations.

When electrical equipment fails, the cause of the failure should be analyzed first, so as to accurately find out the electrical components that have failed.

2. Key points of cantilever crane design:

1. The jog performance of the cantilever crane is better, and the stable speed of the single rope is not more than 2m/min;

2. The main luffing force must be limited, and a force sensor can be installed on the luffing rope or the main luffing tension plate;

3. The super lift device with vertical oil cylinder needs to be equipped with a pressure sensor to detect whether the force on both sides of the pull plate is balanced, and display the force of the two on the display screen, the user can choose to operate the two cylinders synchronously or adjust separately;

4. Overlifting the mast needs to install an angle sensor, and use its value to calculate the amplitude of overlifting the mast;

5. If the horizontal cylinder type is capable of stepless luffing, it needs to be equipped with a length sensor, otherwise the positioning pin can be used in a certain range to ensure the range of the overlifting counterweight.

The above is a brief introduction about "Maintenance, adjustment and design of cantilever cranes?"