| Product Type: | BX Wall mounted jib crane |

|---|---|

| Lifting Capacity: | 0.25 to 10 ton |

| Span: | 10m |

| Lifting Height: | 3m to 6m |

| Working Class: | A3 |

| Ambient Temperature: | -20~40℃ |

Wall bracket & wall mounted jib crane, with cantilever / tie rod jib arm for workshop & workstation material handling. Design your wall mounted jib crane !Wall bracket & wall mounted jib crane, with cantilever / tie rod jib arm for workshop & workstation material handling. Design your wall mounted jib crane !Without taking up any floor space, the Wall Mounted Jib Crane can be mounted directly on profile steel, concrete columns, walls, or other self-standing equipment.A wall-mounted jib crane is a cantilevered boom arm that includes a support, a jib device, and an electric hoist.

The 180-degree rotating wall mounted jib crane mounts effortlessly to any large structural steel building column at any required height.

Types of wall mounted or column mounted jib cranes

Based on cantilever design of the wall mounted jib cranes, they can be grouped into the following types:

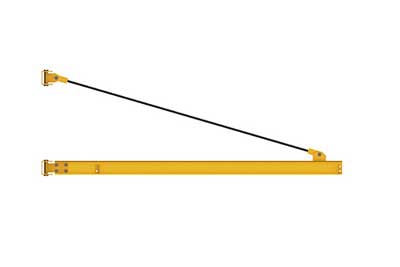

Tie rod wall mounted jib crane

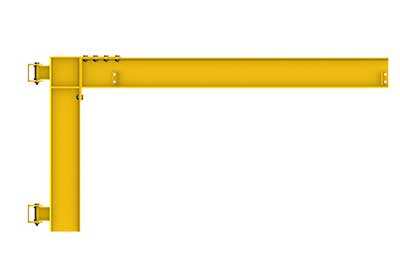

Tie rod wall mounted jib crane Cantilever wall mounted jib crane

Cantilever wall mounted jib craneMounting systems of wall mounted jib cranes

- Wall mounting, which employs threaded rods that pass through the wall and are secured with counter plates and nuts.

- Anchor bolts and a wall bracket encircle the pillar.

- Anchor bolts (threaded rods) max. 1000 mm, bracket plate max. 500 mm.

- Upon request, alternative mounting options are available.

- Mounting supports and walls structureare the responsibility of the client.

Accessories of wall mounted jibs

- Slew stoppers (buffers) can be installed in-place for a fixed slewing range.

- During slewing, the slewing brake is used to control the boom speed. Recommended for boom lengths greater than 5 meters and headroom greater than 4 meters. This keeps the boom from moving about uncontrollably.

- Locking device that secures the boom in place.

Advantages of wall mounted crane

- Improved operation simplicity

- Maximum operational security

- Easy to assemble

- Including complete electrical equipment with delivery

- Switch with a lockable mains connection

Applications of wall mounted jib cranes

- Workshops, warehouses, assembly lines, docks, storage, and ports are just a few of the places wherethe wall mounted cranes areused.

- The typical wall mounted jibs areparticularly suited to short-distance, frequent, and intensive hoisting operations, with qualities such as high efficiency, energy efficiency, labor savings, occupying less space, ease of operation and maintenance, and so on.

- This wall-mounted jib crane requires no modifications to the structure of the building in which it is put and takes up little space, yet it allows things to be transported in three dimensions.

Tie rod wall mounted jib crane with electric wire rope electric hoist

Tie rod wall mounted jib crane with electric wire rope electric hoist Kbk closed track tie rod wall mounted jib crane

Kbk closed track tie rod wall mounted jib crane H beam cantilever with upper braced wall mounted jib crane

H beam cantilever with upper braced wall mounted jib crane Light duty tie rod wall mounted jib with H beam arm & mini hoist

Light duty tie rod wall mounted jib with H beam arm & mini hoist Column bracket jib crane with cantilever design

Column bracket jib crane with cantilever design Wall mounted jib crane with electric chain hoist

Wall mounted jib crane with electric chain hoist Cantilever wall bracket jib crane

Cantilever wall bracket jib crane Wall column mounted cantilever jib crane

Wall column mounted cantilever jib craneSafety devices of wall mounted jib cranes

The crane's standard configuration is for the trolley and crane to both have a step-less frequency conversion control system, with features such as stable braking, accurate location, and reliable performance, which allows the wall mountedcrane to travel steadily and quickly, solving the swingproblem of loads.

The wall mountedcrane's supremacy is demonstrated throughout the process, notably in the frequent operations. The ideal braking system, which can be adjusted by itself and is dustproof, greatly increases safety and reliability. It can beused over 1 million times. Hardening and polishing the tooth surface ensures that thecrane operatedsmoothly.

没有评论:

发表评论