| Product Type: | MG, truss girder gantry |

|---|---|

| Lifting Capacity: | 5-100tons |

| Span: | 22-40m |

| Lifting Height: | Hoist or trolley or winch |

| Working Class: | A3-A5 |

| Ambient Temperature: | -20~40℃ |

Truss gantry crane is a kind of gantry crane with truss steel structure, and it can be with single beam Truss gantry crane or double beam Truss gantry crane as needed. It is mainly used to load, unload or extract materials and goods on outdoor occasions. The Truss gantry crane adopts electric hoist or trolley as its lifting mechanism, and the lifting mechanism mainly includes motor, brake, reducer, drum and pulley block. The motor drives the drum to rotate to let out or in the cable via reducer to lower or lift heavy loads.

Truss gantry cranes are available in a variety of configurations to meet a variety of material handling requirements. There are two types of truss gantry cranes: single girder truss gantry cranes and double girder truss gantry cranes, which can also be semi-gantry truss gantry cranes/ single leg truss girder gantry crane as needed.

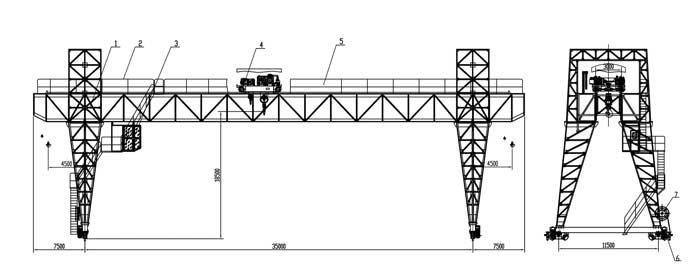

Truss type double girder gantry crane

Truss type double girder gantry crane Box type double girder gantry crane

Box type double girder gantry craneDouble girder truss gantry crane

Double girder truss gantry crane has two truss girder beams and its electric trolley usually travel along the track on the top of the beams, and the truss gantry crane travels along its track on the ground. When the double girder gantry crane is designed with cantilever on one side or both side there should be saddle equipped with the double girder crane; if there is no cantilever required, there is no need to set the saddle on the truss gantry crane.

Features of double girder truss gantry crane

- The purpose of designing and manufacturing a truss gantry crane is to meet current national criteria for laws and standards, as well as the need to use it in extreme weather conditions.

- The truss gantry crane's primary and auxiliary legs can be removed for easier travel and lower shipping costs.

- It is an environmental machine that conforms with all applicable environmental rules and regulations.

- The main girder of the truss gantry crane is made of a triangular truss, which strengthens the entire structure, reduces weight, and improves wind resistance.

- Thermal expansion seamless steel legs of the truss gantry crane are jointing with (or truss legs) the main girder and the ground girder are bolted or pined to the gantry supporting legs. .

- Stable steel gantry structure, easy installation and removal.

- Wind resistance is class 6, non-working wind resistance is 11.

- The truss gantry crane can adopt ground control or cab control.

Truss girder - main parts and componets of double girder truss gantry crane

Truss girder - main parts and componets of double girder truss gantry crane Gantry trolley - main parts and componets of double girder truss gantry crane

Gantry trolley - main parts and componets of double girder truss gantry crane Gantry crane driving motor- main parts and componets of double girder truss gantry crane

Gantry crane driving motor- main parts and componets of double girder truss gantry crane Crane hook - main parts and componets of double girder truss gantry crane

Crane hook - main parts and componets of double girder truss gantry craneApplications of truss gantry crane

MG Type Double Girder Gantry Crane with truss gantry design is consisted of bridge, trolley, crane traveling mechanism and electric system. They are widely used for outdoor general material handling and lifting tasks, such as in construction site of highways, bridges, power plants, and other construction workshops.

The truss gantry crane is ideal for medium and heavy-duty lifting jobs in a number of outdoor settings, including the port, railway, shipyard, and quay. Strong winds and storms will not be able to damage the truss construction. As a result, the truss type gantry crane has various benefits, including low weight, low cost, low wheel pressure, and great wind resistance. The truss gantry lifting equipment can be categorized into single girder and double girder constructions based on the distinct girder constructions.

Double girder truss gantry crane applications

Double girder truss gantry crane applications Double girder truss gantry crane for construction site

Double girder truss gantry crane for construction site Double girder truss gantry crane for construction

Double girder truss gantry crane for construction Double girder truss gantry crane for road construction

Double girder truss gantry crane for road constructionWe manufacture multiple types of truss gantry cranes to serve a wide range of industrial applications.And also customized gantry crane systems are also available for your special working conditions and lifting needs. Contact us now to get a free gantry crane quotation.

没有评论:

发表评论