The mining industry relies on highly-specialised lifting equipment for maximum efficiency and minimal downtime. Daniel Searle spoke to some of the leading manufacturers in the sector.

When it comes to providing lifting equipment for the mining sector, one size does not fit all.

- A customised Condra pre-sink portal crane in Mongolia

- Misia supplies lifting equipment to the mining sector in Australia through distributor SPT

- SPT first sold Misia hoists in Australia in 1996

Johannesburg, South Africa-based Condra Cranes produces ranges of cranes and hoists suitable for all types of mining exploration and production, the company explains, tailored to the type of ore and specific operating environment of the individual customer.

The company runs two factories in South Africa and one in each of Bulgaria and Chile, alongside a worldwide network of service agents to support all of its installations. Its full product portfolio includes single- and double-girder overhead cranes, portal cranes, bridge cranes, cantilever cranes and hoists, as well as end carriages, crabs, bottom-blocks, cable-loop systems and other crane components.

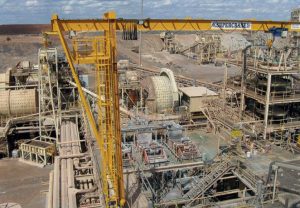

The company highlights a couple of flagship projects: a 47m-lift, 150t overhead maintenance crane at Sishen’s primary crusher plant, which is one of several Condra machines at that South African mine, and its pre-sink portal crane at Oyu Tolgoi in Mongolia.

The pre-sink portal crane reduces by up to 75% the time needed for the pre-sink phase of mine development, explains Condra. It’s a very different type of crane to the level-luffing type of crane traditionally used for pre-sinking, instead using a high-speed, high-lift main hoist to remove excavated spoil vertical by kibble, through an opening in the centre of a drilling stage, positioned by two separate stage-winders mounted on the same portal frame. Lift speed is a metre per second—15 times faster than the four metres per minute found in standard mine workshop applications, says Condra.

More recently, the company also installed a fully-automated grabbing crane at a platinum mine in South Africa. It follows a series of semi-automated systems installed since 2003, all of increasing sophistication. The fully-automated system, which was delivered at the beginning of 2020, is a grabbing machine with dual hoists, variable-speed drives throughout, and four long-travel motors to provide remote crane positioning accurate to within 5mm. The crane is programmed from a remotely-located control room, with onscreen monitoring provided via closed circuit television.

没有评论:

发表评论