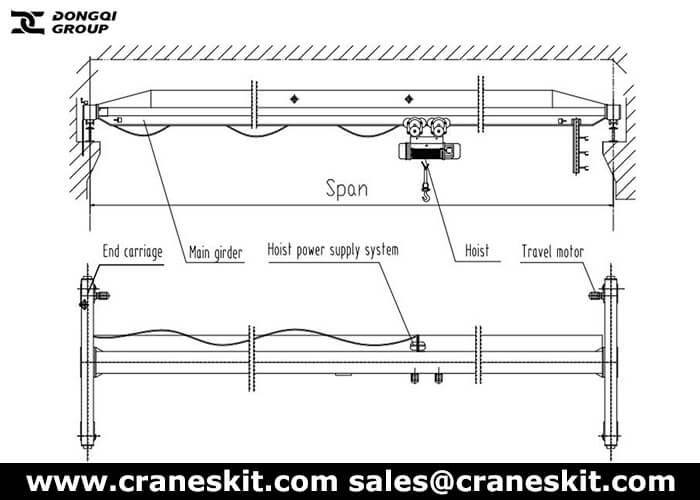

Monorail overhead crane machine, also called single girder overhead crane. With a monorail system, the hoist and trolley run on a single stationary beam. Our engineers can design and build supporting structures, top running single girder crane and underslung overhead crane to meet your application requirement.

5 ton single girder monorail overhead crane for sale to Philippines, is used for new plant expansion. According to our customer’s detailed requirement, our 5 ton monorail overhead crane is designed to travel on top of a runway system that can be either supported by existing building columns.

Monorail Overhead Crane Design Features:

Crane Girder:

- Girders are designed to resist all vertical, horizontal and torsional forces.

- Bridge girders are hot rolled structural steel shapes or welded box girders designed to meet the requirements.

End Trucks:

- End trucks shall be constructed of structural steel tubes, providing a rigid structure.

- Design shall allow easy wheel removal and exchange.

- End trucks can be fitted with shock absorbing bumpers.

- Crane wheels are high strength ductile iron, machined with double flanges and straight treads, flame hardened.

- Wheels are sized to meet the minimum allowable wheel loads.

- The wheel axle assembly can rotate on dual high quality anti-friction, lifetime lubricated bearings having a minimum life of 5,000 hours.

- The end truck to girder connection is bolted for easy removal of end truck.

Wire Rope Hoist:

- The wire rope hoist comprise of rope drum made from seamless tube. Grooves are machined on rope drum for proper support to the wire rope.

- Cast Iron rope band and guide prevents wire rope jumping from grooves.

- The hoisting drive arrangement comprises of motor coupled to an oil lubricated, spur / helical gearbox that in turn provides the motion to the rope drum.

- An electromagnetic fail safe brake prevents accidental lowering of load in the event of power failure.

- Limit switch is provided to prevent over hoisting of hook block. Additional limit switch can also be provided to prevent over lowering of hook block.

Electrification and Controls:

- To supply the electrical power across the crane for bridge, trolley and

- hoist motions, a flat cable festoon system shall be utilized.

- The trolleys that carry the flat cable shall have steel wheels with sealed ball bearings.

- Flat cable connectors can be heat shrinkable, corrosion resistant and flame retardant.

- A magnetic mainline contactor, controlled by momentary on/off switches on the pushbutton shall be included.

- Hoist functions are controlled by magnetic contactor.

- Bridge and trolley functions are controlled by separate variable frequency drives.

- All controls are sized to meet ambient temperatures.

- A cooling system will be provided for each enclosure when the ambient temperature exceeds the maximum allowable operating temperature of the individual Electrical components.

Standard Overhead Crane Includes:

- Wire rope hoist.

- Trolley end stops.

- end carriages.

- Detailed engineering for bridge construction and crane assembly, including two sets of the maintenance manual.

- Complete trolley and sliding push button festoon system with all required mounting hardware.

- Bridge conductor cables pre-wired to quick disconnect plugs.

- Bridge control panel.

- Special kits available upon request.

没有评论:

发表评论