Plastic products are closely related to our lives, and plastic products are inseparable from the support of cranes in the production process. We have designed cranes for many plastic companies, and today we will share a crane design case from Jordan. If your plastic factory needs custom cranes, maybe it will help you.

Plastic company’s design requirements for cranes

In plastic production, different molding methods such as, extrusion, injection molding, blow molding, and rotation molding are used according to different products. Well then, in the process of molding, the changing of molds are necessary, and then we comes to help. Our Jordan client wants to have a lifting system, which would be cost-effective and meets his lifting demands in 4 workshops. After various comparisons, he eventually comes to DQCRANES, the material handling equipment specialist in China.

One of the workshop that needs overhead crane

Design overhead cranes to serve plastic workshops

According to the client requirements and his factory conditions, we designs 4 sets of overhead cranes, two of which are 10 tons and the other two are 5 tons, with special girder and support bucket. These overhead cranes can fully meet his lifting requirements and by large extent lower the costs.

The main points of the overhead crane design in this case

Before we design for this case, through communication with the customer, we have summarized three main points for the crane design plan: the flat top crane girder, the bucket design and the cost-effective crane price. Among them, cost performance is the concern of almost all customers, we have always used this as the design standard

1) Flat top overhead crane girder

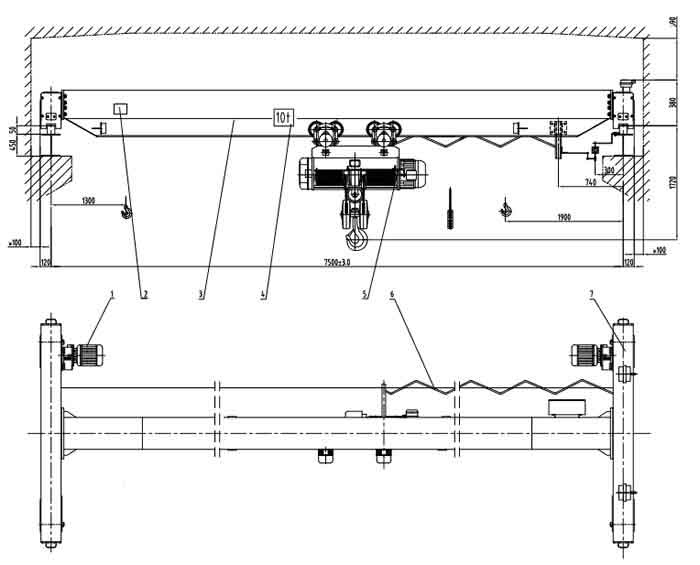

Because of the roof is plat and the lift height is high, our crane engineer designs a very special crane girder which solves the problem pleasantly. The following is the drawing of the LD Type Single Girder Electric Overhead Crane LD 10t-7.5 m A4, which fully satisfies the Jordan client.

1. Crane traveling mechanism, 2. Nameplate installed, 3. Main girder,

4. Tonnage card installed, 5. Electric hoist, 6. Electric device, 7. End girder

The flat top crane girder

2) Crane bucket design

Because of the concrete workshop does have proper buckets and the financial reasons, DQCANES designs the following buckets for him, which solves the problem and lowers his cost.

Crane buckets

3) Cost-effective crane price

On the condition of ensuring crane quality and safety, DQCRANES would like to save the cost as possible as we can. The optimal solution for clients is to provide the high quality material handling equipment with the most cost-effective price.

Crane delivery

As a professional crane manufacturer, we provide a full range of crane services for Jordanian customers, and thus won the trust and orders of customers. In today’s globalization, we have enough ability to design various types of cranes that meet the needs of users for any factory. If you have any questions about the crane, please feel free to contact us.Email: sales010@cranesdq.com

没有评论:

发表评论