European-style single-girder overhead crane is a very excellent crane equipment, it is a compact lifting machine designed strictly in accordance with FEM and DIN standards, with advanced technology and beautiful design. Today we share an order for a European-style single-girder overhead crane from the United States, hoping to help you

When the customer communicated with us for the first time, he expressed his desire to customize a high-performance overhead crane to replace the old one. Our sales manager communicated with the customer in detail and learned that the customer is an agricultural machinery factory. , and obtained the design drawings of the production workshop. After consulting the customer’s feedback and opinions, we finally designed this European standard single-girder overhead crane for the customer.

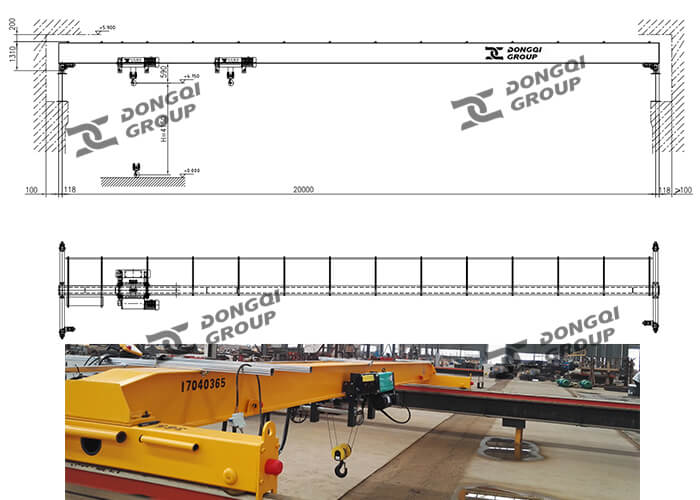

Main parameters of American single girder overhead crane

- Lifting capacity: 6.3+6.3 ton

- Span: 20 meters

- Lifting height: 4.035 meters

- Lifting speed: 2.7 m/min

- CT speed: 21 m/min

- LT speed: 20 m/min

- Power supply : 415v 60hz 3phase

- Motor protection grade: IP54

- Control method: Wireless

- Working class: A5

- Working temperature:-20~+40℃

- Runway Beam (40 m*2) 396*199*7*11mm (40m*2)

- Crane rail SYSTEM (40 m*2) P38 TRACK (40m*2)

- POWER SUPPLY SYSTEM (40m) BUSBAR SYSTEM (40m)

Application of HD single girder overhead crane in the United States

The European standard single girder crane is equipped with ND type European wire rope hoist, usually in a range of 1 ton to 16 ton.

HD type electric hoist overhead crane can be widely used in machinery manufacture, metallurgy, petroleum, petrifaction, port, railway, civil aviation, food, paper making, construction, electronics industries workshop, warehouse and other material handling situations, esp. applied to material handling that need precise positioning, large components precise assembly situation.

Key Points of Designing Single Girder Overhead Crane

Invest to know what client really needs:

We checked the working conditions with our US customers, including the factory photos, size and weight of agricultural machinery, plant expansion plan, we know that our customer also need us to provide steel structure.

Customize every details:

After confirming the advantages and disadvantages of the square track and the P-track with our product department and engineer, we recommend the P30 for the customer. The customer then chose the P30, also confirmed to use welded plate.

How to customize overhead crane in United States

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a overhead crane, you can leave a message on the website or email, tell us the following information, and our sales manager will contact you:

- Lifting capacity (ton): __ ?( The rated capacity)

- Lifting height (m):__ ? (Height from hook center to the floor)

- Span (m): __ ? (Distance between rail center)

- Lifting speed (m/min): __ ? ( Single, Dual, Variable)

- Traveling distance (m): __ ? (The length of the rail)

- Work duty: __ ? (How many hours a day? How many times an hour?)

- What material to be lifted: __ ?

- Industrial voltage: __ ? ( like :380V, 50Hz, 3ph )

没有评论:

发表评论