Electric overhead cranes, also known as bridge cranes, are typically powered by conductor bar, festooning or a cable reel. There are pros and cons of each type of electrification. In certain situations, overhead cranes are powered manually by push or hand geared options or with air power.

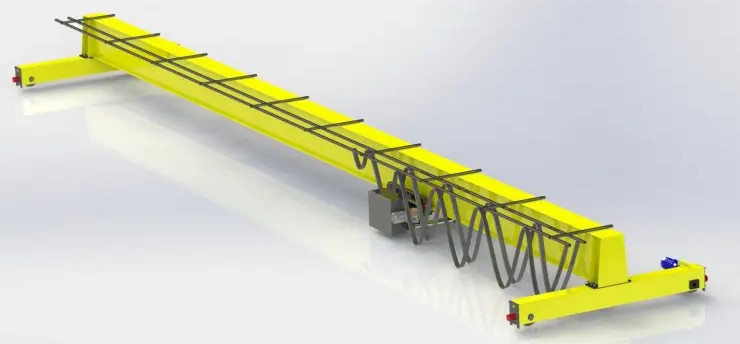

Power supply mode of single girder overhead crane

Dongqi Crane is a professional crane manufacturer, if you have any needs for overhead cranes, please feel free to contact us Email: sales010@cranesdq.com. In this article, we would like to share the power supply method of single-girder overhead cranes.

The commonly used power supply methods for single-girder overhead cranes are divided into two categories, sliding contact line power supply and cable line power supply. The two power supply methods have their own applicable places. For example, the trolley wire is very convenient for maintenance and inspection, and it occupies a relatively small space, but the weather resistance of the operating environment temperature is slightly insufficient, and the flexibility is poor; the cable wire It can be continuously bent and used with the equipment, and has better flexibility. Due to the protection of the outer layer of insulating glue, the wear resistance, oil resistance and corrosion resistance are relatively stronger.

There are two types of cable wires: round wire and flat wire. The number of bending times of the flat wire is greater than that of the round cable, and the service life is long. According to the characteristics, the flat cable is mainly used for mobile laying, and the round cable is used for fixed laying. Cables can also be used for mobile laying.

When arranging crane cables, it is necessary to ensure that the length of each cable is flat, the pressure plate is crimped firmly, and the outer diameter of the same layer of cables is as close as possible to avoid excessive stress on one or a few cables. The cables that need to be suspended should be arranged with a wire harness, so that the wires are neat and orderly. During operation, when the distance between the two adjacent suspension cable trolleys makes the angle between the suspension cables close to 120°, the traction wire rope should be completely straightened and stressed.

When using a cable reel to take up the cable, avoid the cable being worn during the movement. For cables with an outer diameter not greater than 21.5mm, the bottom diameter of the cable reel should be at least 10 times the outer diameter of the cable; for cables with an outer diameter greater than 21.5mm , the bottom diameter of the cable reel should be at least 12.5 times the outer diameter of the cable.

The cable reel of the crane should be able to automatically wind the cable, and the driving torque of the cable reel should not be less than the large wrapping torque required for winding the cable. In the process of laying out the cable, the traction force acting on the cable conductors should be as small as possible. For cables without reinforcing cores, the allowable pulling force acting on the cross section of the copper conductors is 20N/mm2. Regarding the requirements for high cable wrapping speed or high cable self-weight When it is heavy, a reinforced steel wire rope that can accept the required traction force should be added as the core.

During the application process, some customers also value the advantages of the power transmission rails of the trolley line, such as good electrical conductivity, fast heat dissipation, and low impedance value. , configure the corresponding software and hardware. Baowei Crane introduces product features to customers, and recommends feasible solutions for customers’ production value. The right to choose is in the hands of customers. We provide not only products, but also strive to provide better services.

Cable reels, either motorized or manual spring reels, offer a simple solution for powering for overhead cranes while managing large lengths of cable. The reel winds and stores flexible cable and need minimal maintenance. It is easy to install and can be mounted in a fixed position or on a rotating base to allow the cable to extend in more than one direction.

Manually powered cranes operate by either pushing the load or by pulling a hand chain that drives a hand wheel. This method is typically for smaller cranes or for infrequently used maintenance cranes. A hand-geared crane generally maxes out at 5-tons capacity and about a 30 ft span.

To determine the best power source for your crane system, consider factors such as the availability of power and safety considerations for your environment. When in doubt, contact a professional overhead crane installer.

https://www.craneyt.com/how-are-overhead-cranes-powered.html

没有评论:

发表评论