What is SWL

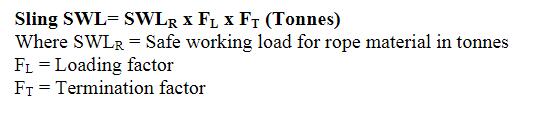

The safe working load (SWL) of a sling is the maximum load that may be lifted after considering the SWL of the sling material, the reeving arrangement and the method of sling termination. For a flexible steel wire rope (FSWR) sling the SWL is given by:

Flexible steel wire rope (FSWR) sling the SWL

The loading factor is a combination of the reeving factor FR and the angle factor FA. The loading factor is given by:

FL = FR x FA

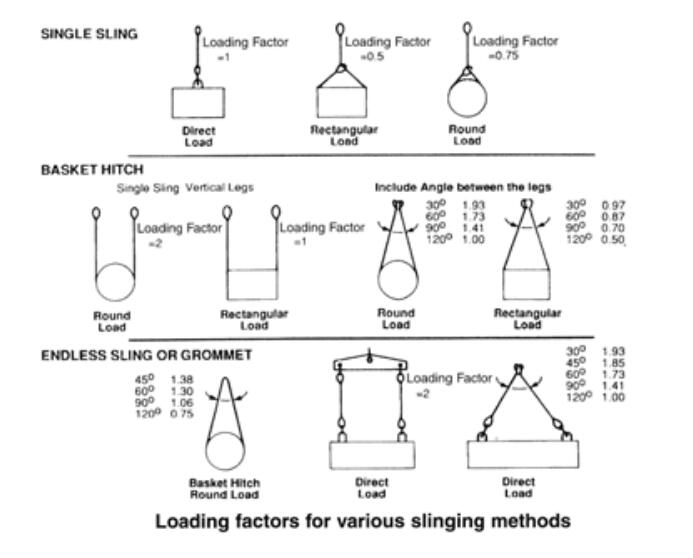

Loading factors for various slinging methods are given in the following diagram which indicates the affect of reeving and sling angle.

For example, a reeved sling around a square load will halve the sling’s lifting capacity. In this situation the loading factor is 0.5.

Loading factors for various slinging methods

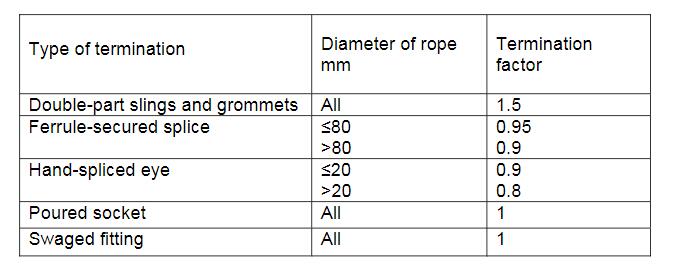

Termination factors for commonly used termination methods

Sling termination factors depend upon the type of termination and rope size. The table above provides termination factors for commonly used termination methods.

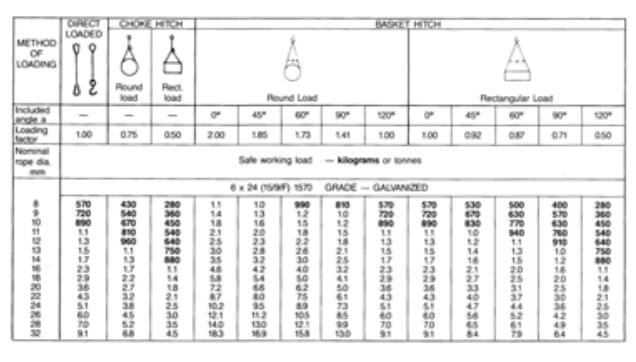

To simplify selection of the appropriate FSWR sling it is usual to combine the safe working load of the rope material with the loading factor to produce a safe working load chart.

The load chart below has been prepared for 6 x 24 – 1570 grade galvanised steel wire rope. The safe working load for various rope sizes and slinging configurations has been combined to enable the SWL to be taken directly from the chart.

The only correction which may need to be made to values taken from the chart will depend upon the method used to terminate the sling.

SWL charts are available for all types of slings and rope. Make sure that you consult the correct chart before lifting.

SWL charts are available for all types of slings and rope

Rule of thumb methods for calculating the SWLs of flexible steel wire rope, chain and fibre rope.

Please note that these methods only give approximate answers.

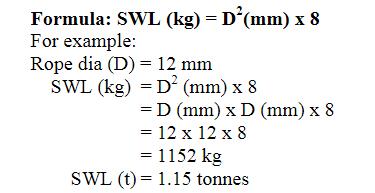

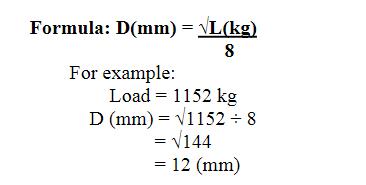

Flexible steel wire rope (FSWR)

To calculate the SWL in kilograms of FSWR square the rope diameter (D) in millimetres (mm) and multiply by 8.

The above equation can be reversed to calculate the diameter (D) in millimetres of FSWR needed to lift a given load. To do this, divide the load (L) in kilograms by 8 and find the square root of the result.

Therefore a FSWR sling of at least 12 mm in diameter is required to lift a 1152 kg load for a straight lift.

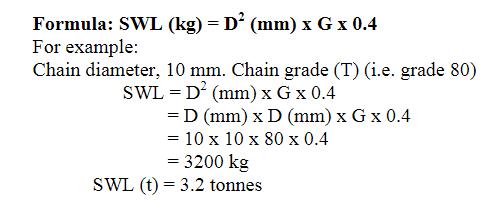

The SWL of chain is determined by the grade (G)

Do not use a chain to lift if it does not have a manufacturer’s tag that gives details of the SWL. Return it to the manufacturer for SWL assessment and retagging.

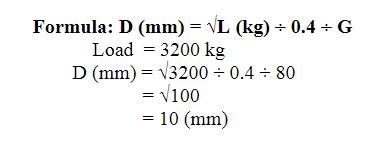

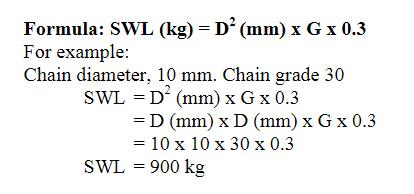

To calculate the SWL of lifting chain in kilograms, multiply the diameter (D) in millimetres (mm) squared, by the grade (G), by either 0.3 or 0.4. For Grade 80 chain, use 0.4, and for Grade 30 or 40 chain, use 0.3.

The above equation can be reversed to calculate the diameter (D) in millimetres of chain needed to lift a given load. To do this, divide the load (L) in kilograms by 0.4 and by the grade (G) and find the square root of the result.

Therefore a Grade 80 chain, 10 mm in diameter is required to lift a load 3200 kg for a straight lift.

Warning: The above formula must not be used for any other load lifting chain which is less than Grade 80.

To calculate the SWL of grade 30 or 40 lifting chain in kilograms, square the diameter (D) in millimetres (mm) and multiply the grade (G) by 0.3.

If you want to know more and more detailed content, you can download the PDF file provided below. If you have any needs for cranes and accessories, you can contact us by Email: sales010@cranesdq.com

https://www.craneyt.com/how-swl-helps-crane-operators-lift-loads-safely.html

没有评论:

发表评论