| Product Type: | CD/MD Electric Wire Rope Hoist |

|---|---|

| Lifting Capacity: | 0.5- 32 ton |

| Span: | - |

| Lifting Height: | 1-100m |

| Working Class: | M3,M4 |

| Ambient Temperature: | -25℃~+40℃ |

Single Speed & Double Speed Electric Wire Rope Hoist

Electric wire rope hoist is a common lifting equipment, which can be mounted on single beam crane, overhead crane, gantry crane and jib crane. With slight modification, electric cable hoist can also be used as winch. Traveling hoist can be installed on various kinds of cranes or suspended on I-beam to do some straight or curve motions. Fixed hoist can be installed on fixed support to do some vertical motions.

Two types of extensively used electric cable hoists are type CD1 and MD1 . Model CD1 electric wire rope hoist has only one normal speed, which can satisfy normal application. Model MD1 electric wire rope hoist provides two speed. At low speed, it can do precise loading and unloading, mounding of sand box, maintenance of machine tools. Thus Model MD1 electric wire rope hoist is more widely used than Model CD1.

Single speed electric wire rope hoist

Single speed electric wire rope hoist Double speed electric wire rope hoist

Double speed electric wire rope hoistSpecifications of Electric Wire Rope Hoist

- Capacity of Electric Wire Rope Hoist: 0.5-32 ton

- Lifting Height: 1-100m or as your requirement

- Working Class: M3~M4

- Applicable Temperature: -25℃~+40℃

- Applicable Humidity: ≤85%

- Applicable Altitude: below 1000m

- Applicable Power: 3-phase 380v 50HZ(which can be customized according to customer's requirements)

- Customized Hoist: It can be designed and manufactured according to requirements.

CD Single Speed Hoist v.s. MD Double Speed Hoist

- The CD1 Single Speed Wire Rope Hoist has only one regular speed, which is sufficient for most applications.

- The MD1 Double Speed Wire Rope Hoist features two speeds: normal and low. It can handle precision loading and unloading, sandbox mounding, machine tool maintenance, and so on at low speeds. MD1 is more popular than CD1.

- The MD1 Double Speed hoist has a lifting auxiliary motor and slower driving equipment than the CD1, resulting in hoisting speeds of 8 and 0.8 meters per minute, respectively.

- The MD1type of Double Speed wire rope electric hoist is slightly more expensive than the CD1 Single Speed model.

Therefore, for general material handling, the operation can be conducted by CD1 single speed wire rope electric hoist, and on the other hand, for precision installation, clamping work, sand casting and other requirements for precise hoisting operation and positioning, it is recommended to choose MD1 double speed electric hoist.

CD/MD Wire Rope v.s. Electric Chain Hoist

Compared with chain hoist, rope hoists is of faster lifting speed and a maximum lifting height up to 100 meters. It also gets more easier to disassemble and maintain. Moreover, it can be designed and manufactured according to client’s requirements.

Single speed electric wire rope hoist

Single speed electric wire rope hoist

Electric chain hoist for single girder overhead crane

Application range of electric duel speed wire rope hoist

Electric wire rope hoist is the ideal hoist options for very high-capacity lifting applications where frequent use throughout the day will occur. Since the large components allow them to withstands the intense heat created by constant lifting.

Electric wire rope hoist is widely used in factories, mines, harbors, warehouses, cargo storage areas and shops.

Small portable gantry crane with lectric wire rope hoist

Small portable gantry crane with lectric wire rope hoist Double girder overhead crane with double rail wire rope hoist trolley

Double girder overhead crane with double rail wire rope hoist trolley  Single girder overhead crane with suspesion wire rope hoist

Single girder overhead crane with suspesion wire rope hoist  Electric wire rope hoist for single girder crane installation

Electric wire rope hoist for single girder crane installationAdvantages of electric wire rope hoist

- Rope hoist with compact structure, light weight.

- Electric cable hoist of high universality and lifting capacity.

- Electric rope hoist of easy operation, maintenance and stable lifting.

- Electric wire rope hoist of high efficiency and longevity.

- Rope hoist with high safety and reliability.

Details of Electric Wire Rope Hoist

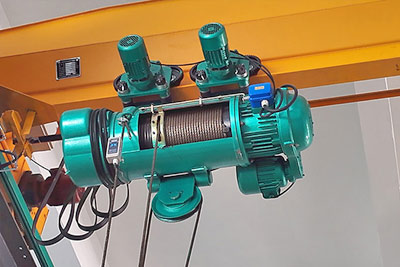

Electric cable hoist consists of electric motors, a gearbox, a rope drum with rope guides, and a large wire rope fixed with a hook. Wire rope hoists lift loads by utilizing a grooved drum around which the wire rope is wrapped. CD1 and MD1 type electric wire rope hoist mainly consists of three parts, the first is lifting mechanism, the second is traveling mechanism (only for traveling hoist ), and the last is electrical equipment.

Details of Electric Wire Rope Hoist

CD1 and MD1 type electric wire rope hoist mainly consists of three parts, the first is lifting mechanism, the second is traveling mechanism (only for traveling hoist ), and the last is electrical equipment.

Lifting mechanism

Lifting Motor of electric wire rope hoist

- Lifting motor drive winding drum rotating through coupling and hollow spindle of reducer, in order to make wire rope of drum drive the hook up and down.

- Model CD1 hoist is fitted with ZD type single speed motor, Model MD1 with ZDS type double speed motor, its ratio of usual speed and low speed is 10:1.

- The lifting motor of electric wire rope hoist uses tapered rotor three-phase asynchronous braking motors which is small in volume and light in weight with the feature of high starting torque, effective braking, compact structure to achieve a stable operation and frequent direct traveling during course of working discontinuously.

- The lifting motor of electric cable hoist is of B or F class insulation, IP44, IP54 protection and safe to use, convenient to maintain.

Rope Drum of electric cable hoist

- The drum is the central part of electric wire rope hoist. It is connected with travelling mechanism above through balance beam, with reducer and motor both sides, and with wire rope and hook below and installed limited guide bar equipment to the up front of the outer cover.

- Electric wire rope hoist’s rope drum is made of cast iron or seamless steel tube, which is light in weight, transmit the dynamic force by splines.

- Coil casing including rope guide is made of superior cast iron which is of high intensity.

Reducer of electric cable hoist

- All reducers of electric cable hoist adopt 3-level bevel gear. The gear and axes are made of alloy steel.

- Proper heat treatment is conducted to ensure their reliability and service life.

- Finally, the box-body and box-cover of rope hoist are made of superior cast-iron. Both are well shake-reducing and sealed tightly.

Hook of electric wire rope hoist

- The hook of electric cable hoist is forged with special steel and connected to the pulley assembly through thrust ball bearing to make the hook rotate freely.

- Hooks no more than 5 ton lifting capacity are of single-pulley style and above 10 ton are of double-pulley style.

Travelling mechanism (only for travelling hoist)

Components of travelling mechanism

- It consists of motorized trolley, travelling reducer, travelling motor, driven trolley, etc. The mechanism do reciprocating motion through main engine driven by side plate and drum.

- lThe wheel tread is straight when used with box type girder or H beam, is circular arc when used with I-beam.

- lIts travelling speed is 20m/min, but 30m/min is possible; if 1~5t capacity with 12m or higher lifting height, a driven trolley is necessary.

Running trolleyof electric wire rope hoist

Traveling motor

- Use tapered rotor of three-phase asynchronous braking motors.

- Stable starting,safe braking, can be used with reducer.

- B grade or F grade of insulation, closed structure, motor protection grade is IP44 or IP54.

Travelling motor of wire rope hoist

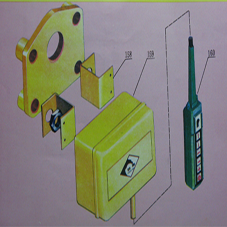

Electrical equipment of wire rope hoist

Components of electrical equipment

- The electrical mechanism of electric wire rope hoist consists of electric control box, limiter, button switch, connecting wire etc.

- According to the marked direction on the button switch, press the button correctly and control the hoist through the on-and-off of the relay in the control box.

- Electric cable hoist’operating voltage is usually 36V.

Safety protection of rope hoist

Safety protection of rope hoist- The accurate gear drive limiter is used as upper and lower limit, which can reliably cut off power circuit if hook moves to the upper or lower limit so as to stop the motor.

- Overload protector: the electric wire rope hoist is using electronic overload protector, so that the total lifting weight will not exceed the rated lifting weight; if the pulling force of steel rope is more than 105% of the rated capacity, the overload protector device would automatic cut off lifting loop.

- Emergency stop protection, Over-heat protection of hoisting motor, Over-current protection, Phase protection, Voltage lower protection.

Control way of rope hoist

Pendent line control

- Its 36V control voltage is safety for human being.

- It is easy to control, no additional driver necessary, and it operate following the travelling of hoist.

- It is connected with the electric trolley suspended under trolley.

- Its protection class are IP54 IP55.

Remote control

- Its 24V control voltage safety for human being.

- Its remote distance: not less than 100 meters.

- It is easy to control, no additional driver necessary, to operate more freely on the ground.

- It has tens of thousands of connection frequency points, non-interference with each other.

- Its protection class are IP54 IP55. Its case is made of welded steel plate.

If you are searching for a versatile lifting equipment, Yuantai electric wire rope hoist will be a nice choice! Welcome your consultation anytime, and we’ll try our best to give you a satisfying answer!

Electric wire rope hoist lifting motor

Electric wire rope hoist lifting motor

没有评论:

发表评论