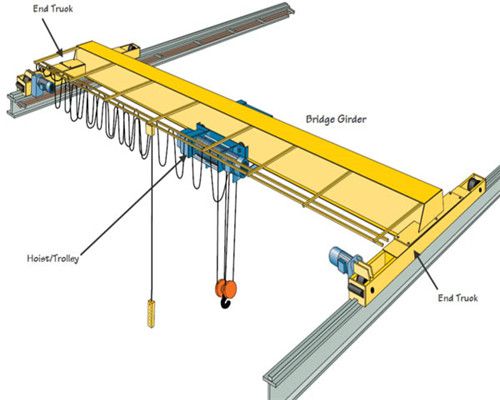

How a Single Girder EOT Crane works

The Single Girder EOT Crane moves over the rails placed on the top of crane runway or Gantry Girders. The crane mainly comprise of bridge girder made from rolled sections such as I beams / U beams or fabricated box section. The bridge girder is supported on two end carriages, each housing a pair of wheels. The wheels are driven by motor gearbox units. A wire rope hoist is suspended below the bridge girder. The crane can be operated through pendent station hanging from wire rope hoist or through radio remote control. The pendent station can be made to move independent of hoist movement as per customer's choice.

Composition of wire rope hoist

The wire rope hoist comprise of rope drum made from seamless tube. Grooves are machined on rope drum for proper support to the wire rope. Cast Iron rope band and guide prevents wire rope jumping from grooves. The hoisting drive arrangement comprises of motor coupled to an oil lubricated, spur / helical gearbox that in turn provides the motion to the rope drum. An electromagnetic fail safe brake prevents accidental lowering of load in the event of power failure. Limit switch is provided to prevent over hoisting of hook block. Additional limit switch can also be provided to prevent over lowering of hook block.

The cross movement of hoist is achieved through the movement of wheels supported on the beam / box flange. The drive to the wheels is provided through an electric motor-gearbox unit. Fail safe brake and limit switch are provided as additional features is so desired by customer.

Power supply to the wire rope hoist is through festoon cable system. The flexible cables are supported by cable hanger or cable trolleys that move on either taught wire or enclosed C track depending on customer choice.

The single girder cranes find their application mainly for capacities up to 20 MT and Span up to 25 Meters. These are commonly used for light and medium workshop duty applications. However, in rare cases the single girder cranes are also used for hot metal ladle handling as well as with grab bucket.

Single Girder EOT Cranes introduction

Dongqi crane is engaged in manufacture of single girder EOT cranes includes Material Handling EOT Cranes with capacity ranging from 0.5 ton to 40 ton. These single girder overhead cranes are fabricated by us keeping into consideration the Indian standards. Dimensionally accurate and functionally superior, these cranes are immensely used in diverse industries for material handling. Sturdily constructed, these cranes serve the application demands of different industries for a long period of time.

Single Girder EOT Cranes design

The single girder overhead cranes (single girder EOT cranes) is very convenient equipment for material handling even in the small production units and warehouses. The reduced wheel loads combined with very low headroom standard hoists provide outstanding value. These material handling overhead cranes can fitted in different floor areas by using various fixing arrangements and modifications in design. The accurate dimensions result in optimal hook position providing exceptional travel characteristic. Generally there is minimum safety distance with the ceiling of the building for overhead cranes with load capacity range of up to 10 T. This provides a typical advantages of utilizing the space at its best even in the buildings with unfavourable dimension. We can design and efficiently install traveling cranes in available space by using different fixing arrangements. To accomplish the project with perfection, all we need is accurate dimension of the building during the planning stage. We specialize in custom designing cranes based on the specific needs of the clients.

没有评论:

发表评论