The electric trolley gantry crane is a mid –light type gantry crane, equipped with electric and crane hooks, with the obvious features of “ L” shape legs, which makes the crane more convenient for handling cargo with long length, such as, steel pipe, etc. The lifting capacity of the electric trolley gantry crane is 5 to 32 ton and working class is A5 and A6. The parameters are as following:

- Product Type: L

- Lifting Capacity: 5~32t

- Span Length: 18~35m

- Working Class: A5, A6

- Ambient Temperature: -20~40℃

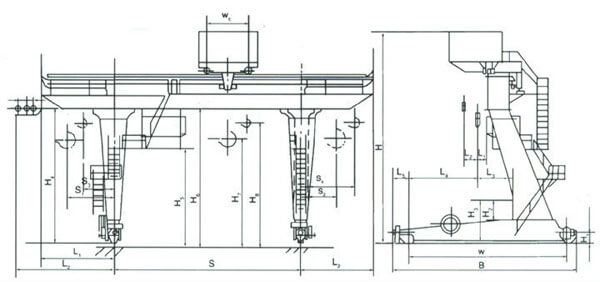

L type gantry crane drawing

Electric Hoist Gantry Crane-Single Girder L Type Gantry Crane parameter

Electric Hoist Gantry Crane-Single Girder L Type Gantry Crane Description

Specifications

| capacity(t) | Main | t | 32 | ||||

| Aux. | 5 | ||||||

| Span | m | 18 | 22 | 26 | 30 | 35 | |

| Lifting Height | Main | 12 | |||||

| Aux. | 12 | ||||||

| Working Duty | A5 | ||||||

| Speed | Main | m/min | 8 | ||||

| Aux. | 20 | ||||||

| Crab Traveling | 39 | ||||||

| Trolley Traveling | 49 | 54 | |||||

| Crane Rail | 43kg/m | ||||||

| Power Supply | 380V 50Hz 3-Phase | ||||||

Application

Light dead weight and strong lifting weight. Widely used at open or room ground and warehouses, yards etc. Ground controlling and room controlling.

Description

1. L single main beam hook hoist gantry/door crane is mainly composed of gantry, crane crab, and trolley traveling mechanism, cab and electric control system.

2. The gantry is of a box-shape structure. The crab adopts vertical reaction wheel when the lifting load is below 20t, and horizontal reaction wheel when above 20t to run at the girder side.

3. The girder is of single-girder bias track and the leg is L-shaped, so that the lifting space is large and the spanning ability is strong, making it easy to covey articles from the span to under the jib.

4.The closed cab is employed for operation, where there are adjustable seat, insulating mat on the floor, toughened glass for the window, fire extinguisher, electric fan and auxiliary equipment such as air conditioner, acoustic alarm and interphone which can be furnished as required by users.

Feature

1. Crane material:Q235,Q345B/Q345D

2. Strong box type, no-welding joint strong box type, by machine hand, strong and beautiful.

3. Wheelsare vacuum casting by ourselves, intermediate frequency quenching.

4. Wheels,wirerope,drum,gears,coupling are manufactured by our CNC machines.

5. Nanjing special or Nanjing Brand motor,top quality in China.

6. Eletrical equipments:Siemens or Schneider brand.

7. Control method:Cabin control,wireless remote control or pendant control,you can choose two of them (According to your demand to design the gantry crane.)

Safety system:

1. Weight overload protection device.

2. Top quality long time bearing polyurethane materials buffer.

3. Crane travelling limit switch.

4. Voltage lower protection function.

5. Emergency stop system.

6. Current overload protection system and so on!

| Type/Model | L type single beam gantry crane |

| Advantage: | Mid-light type crane, Special good performance for long and heavy goods |

| Structure | Main Beam, Ground Truck, Hoist trolley, Complete Electrical system and control system |

| Quality Standard | ISO 9001: 2000 ISO 14001: 2004 and OHSAS 18001 |

| Motor | Slipring motors, dust proof construction foot / flange mounted TESC / TEFC |

| Brakes: | Independent Hydraulic Brake or built-in mechanical brake |

| Gear Box: | All gears & pinions running on antifriction type ball / roller bearings in totally enclosed oil bath giving constant splash lubrication |

| Limit Switch | Safety limit switches for stoppers will be provided to prevent over traveling in all motions. |

| Optional Features: | Wireless Radio Remote control Variable speed at all motions available Flameproof Anti-explosion Cabin Operated PLC automatic Control system |

Electric Hoist Gantry Crane-Single Girder L Type Gantry Crane After sale

Packaging & Shipping

1. Main girder, ground girder and support legs will be packed by bubble paper;

2. All the electrical parts will be packed by plywood box;

3. Rails will be naked within container.

Our Services

1. Once provide us the requirement, the details technical data and CAD drawing will provide you.

2. Strict quality control system, supervision the work to ensure the best crane for you.

3. Strict production line, make sure manufacture the goods on time.

4. Best cooperation forwarder provide the soonest and reliable service for our goods.

5. If needed, senior engineers can be your side do the installation guide and training.

FAQ

1. Is your product customized?

Thanks for your question. Yes, because the working condition are different, all our products are customized depending on detail requirement! So if you give us more information about the lift capacity, span, lift height, power source and other specials, we will give you a very quick quote!

2. How many operating methods for my selection?

Thanks for your question. The standard operating methods we provide is pendent controller with push buttons. Meanwhile, we can also provide the remote control with push buttons and the cabin (space capsule seat) control with joystick. You can choose any of them, just tell us!

3. What’s the max lifting capacity of the crane?

Thanks for your question. The max. Lifting capacity of our standard crane are up to 600 ton (the electric hoist are up to 80 t). If this can’t satisfy your working requirement. Please contact us for special customized.

4. The space of my workshop is limited, can the crane ok for mine?

Thanks for your question. For low headroom workshop, we have the Special products. The detail dimension please consult our professional engineer.

5. Can the crane work in hazardous environment?

Thanks for your question. .For hazardous environment, please consult our professional sales manager.

Our certificate

Various types of gantry cranes

How to customize a gantry crane

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a gantry crane, you can leave a message on the website or Email: sales010@cranesdq.com, tell us the following information, and our sales manager will contact you:

- Lifting capacity (ton): __ ?( The rated capacity)

- Lifting height (m):__ ? (Height from hook center to the floor)

- Span (m): __ ? (Distance between rail center)

- Lifting speed (m/min): __ ? ( Single, Dual, Variable)

- Traveling distance (m): __ ? (The length of the rail)

- Work duty: __ ? (How many hours a day? How many times an hour?)

- What material to be lifted: __ ?

- Industrial voltage: __ ? ( like :380V, 50Hz, 3ph )

没有评论:

发表评论