What is the RTG Crane?

A RTG crane (rubber tyred gantry crane) is a mobile gantry crane used in intermodal operations to ground or stack containers. Inbound containers are stored for future pickup by drayage trucks, and outbound are stored for future loading onto vessels. RTG crane machine typically straddle multiple lanes, with one lane reserved for container transfers.

RTG Crane Parts:

RTG crane generally includes the following units: steel frame, hoisting mechanism, minimum slewing mechanism, and spreader anti-shaking mechanism, crane travel mechanism, turning mechanism, trolley traverse mechanism, container spreader, diesel generating sets, electrical equipment and other accessory equipment for safety.

RTG Crane Height:

Rubber tyre gantry cranes (RTGs) are available with spans of between five and nine containers wide (plus a truck lane) and with hoisting heights from 1 over 3 to 1 over 6 containers high. Supplied with eight rope reeving anti-sway system and drive systems, the RTG delivers exceptional productivity and reliability in container stacking.

RTG Crane Design Features:

The RTG has a rigid and stable steel structure allowing precise handling with smooth movements even at high speeds. High quality standard achieved, with ease of maintenance results in minimum downtime, increasing throughput per RTG unit. Precise control using simultaneous drive motion removes the need for a headblock or side shift. Available in either eight or 16 wheel configuration with numerous productivity options from DGPS and auto steering to stack profiling and automation.

Service Offered by DQ Cranes to Singapore Customer:

Our Singapore customer need to use this rtg crane in container terminal to handling materials. Based on this request, Dongqi has been soliciting feedback and opinions from our customer. Our engineers and experts have designed and improved our rubber tyred gantry crane.

Dongqi rubber tire gantry crane delivers optimized design, high performance, lighter weight, short delivery cycle, more economical operation, easier maintenance, low energy consumption and high reliability. Furthermore, clients could select from a range of optional functionalists. Production can be assembled to meet customer requirements more precisely.

RTG Crane Specification:

Main lifting mechanism

- Lifting load:4x25t

- Lifting height:6m

- Lifting speed:0-1.5m/min

- Working class:M3

- Pulley ratio:4

- Wire rope:6x37-20-1670-IWRC

- Motor:YZP-6/11KW

- Reducer:ZQ400

- Brake:YWZ-300/45

Long traveling mechanism

- Traveling load:4X25t

- Traveling speed:1.7-17 m/min Inverter control

- Working class:M3

- Tyre diameter:φ1600

- Ground press:0.8Mpa

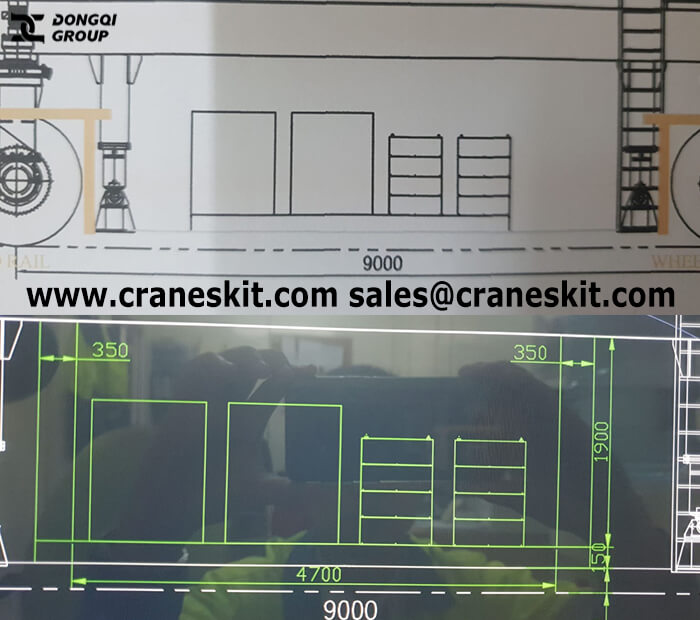

- Span:11.5m

- Base distance:9m

- Adapt:Concrete pavement or rammed foundation pavement

- Motor: 5.5KW×4

- Reducer:K107

- ⑾Ratio:141

Cross traveling mechanism (one set)

- Traveling load:2x25t

- Traveling speed:0-4m/min

- Working class:M3

- Wheel diameter:φ400

- Max wheel press:17t

- Gauge:7.3m

- Base distance:1.6m

- Motor: 2X1.5KW

- Reducer:BLED2215

- ⑾Ratio:121

Standard Safety Devices:

- Automatic rectify deviation control.

- Weight overload protection device.

- Top quality polyurethane buffer.

- Phase protection.

- Lifting limit switch,cross traveling limit switch,long traveling limit switch.

- Voltage lower protection function.

- Emergency stop system.

- Current overload protection system.

- Lighting system.

- Audio and video alarm system.

没有评论:

发表评论