As a necessary mechanical equipment for infrastructure construction, cranes are used in various places. As a special production place, the crane equipment required by the cement plant also requires special customization. The case shared today comes from a gantry crane customized by a cement plant in Pakistan.

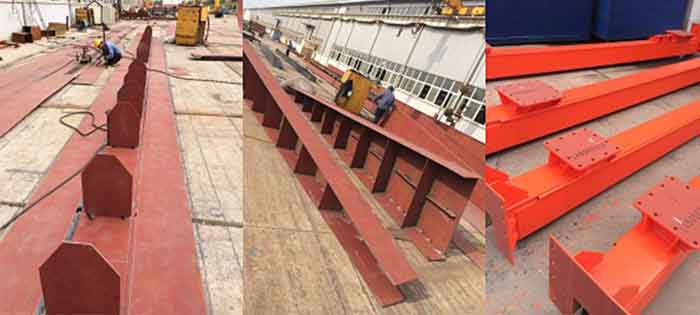

Customized Gantry Crane for Pakistan Cement Plant

As for the Central Asia gantry crane project the main information is as follow:

- Project Name: Construction of cement production line

- Industry: Building Materials Manufacturing Industry

- Crane: Gantry crane main profile:

- Quantity: 2 sets

- Gantry crane Model: MH5t-24m

- Gantry crane span: 24 meters

- Gantry crane lifting height: 9 m

- Gantry crane hanging outside: one side of hanging beam with 5 meters cantilever

- Gantry crane working level: A4

- Gantry crane operation: ground operate, driver’s cabin control

- Gantry crane long traveling distance: 150 meters

- Gantry crane lifting materials: sand, cement and cement products

- Gantry crane configuration: Schneider Electric, soft start motor, motor protection class IP54, insulation class F.

- Gantry crane ambient temperature: -40 ℃ -40 ℃

The electric hoist gantry crane using under the environment with perennial big wind speed, big wind sand, the crane installed with rail clamp, anemometer, electrical box with temperature control device, and anti-cold cables, etc. Hoisting mechanism traveling track using C-type steel slide.

Pakistani customers often have more problems with the price when customizing cranes. However, due to the special working environment of cranes, during the customization period, they should pay more attention to the working environment of the crane and whether there are special needs to avoid the inability to adapt to the working environment in the later period. Causes a malfunction. If you have any needs on the crane, please feel free to contact us

没有评论:

发表评论