In various industries in the industrial sector, when steel products need to be processed, it is necessary to use electromagnetic cranes. Electromagnetic cranes use electromagnets as crane hooks to attract the steel materials that need to be processed.

What is an electromagnetic crane?

Cranes with a magnet or magnet system on the hook working together, is what people calls magnetic crane. They operate using a magnetic field that is generated by an electric current passing through windings around the magnet. The magnet is turned on and off when needed by the electric current.

These cranes have a simple job: moving metals from one area to another. The magnet picks up metals, moves them to where they are supposed to go, and the magnet is cut off, releasing the metals.

Although all iron and steel products can be handled by electromagnetic cranes, we have designed and manufactured different types of electromagnetic cranes for different forms of iron and steel products, so that customers can handle materials more conveniently.

Classification and application of electromagnetic crane

We carry different materials by making different types of electromagnets as hooks. We will describe the types and application scenarios of electromagnets one by one

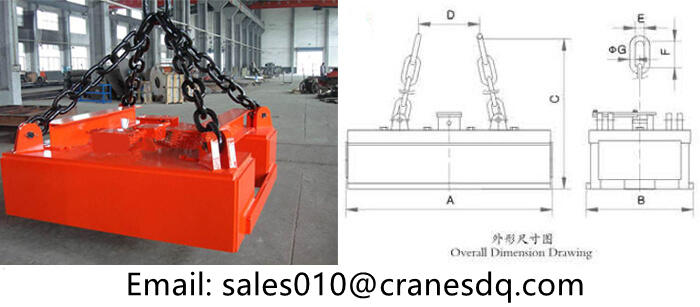

MW5 Series Lifting Electromagnet

MW5 series lifting electromagnets are suitable for cast ingot, steel ball, pig iron, machine chip, various kinds of steel scraps, return scraps, cropping, baling scraps and so on in foundry factories and iron powder in coal washeries. During slag disposal process, it can remove large size of iron at initial step. Outlet box has two chambers, an extra-thick fender and an anti-twist setting. There are three excitation options: rated voltage DC220V; strong excitation; over excitation.

MW61 Series Lifting Electromagnet

MW61 series lifting electromagnet can load and unload steel scraps efficiently at narrow trunk-shaped container.MW61 series lifting electromagnet is called oval shape electromagnet owing to its special half-round structure. As chute dimensions in various steel companies are different, the following sample is just for your reference, and we can make the specific one according to your requirement.

Note: Exactly speaking, there are various kinds of steel scraps (In “Steel Scrap GB 4223-2004”, they are divided into heavy type, medium type, small type, aggregate type, light type, etc.) As the figure, size, weight and bulk density are different, the magnetic circuit of the electromagnet should be designed separately. However we can produce the most suitable one for you to ensure the best performance according to your scrap.

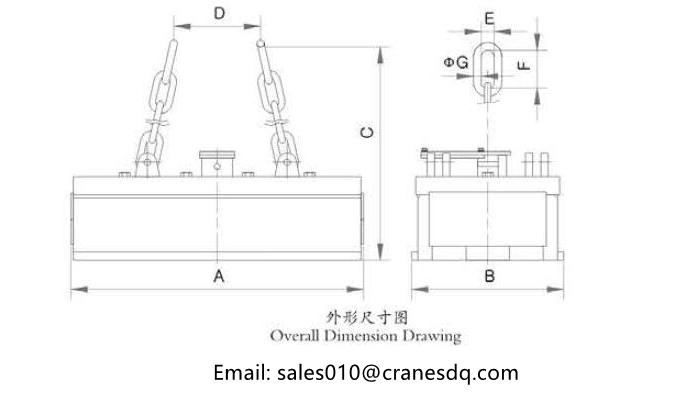

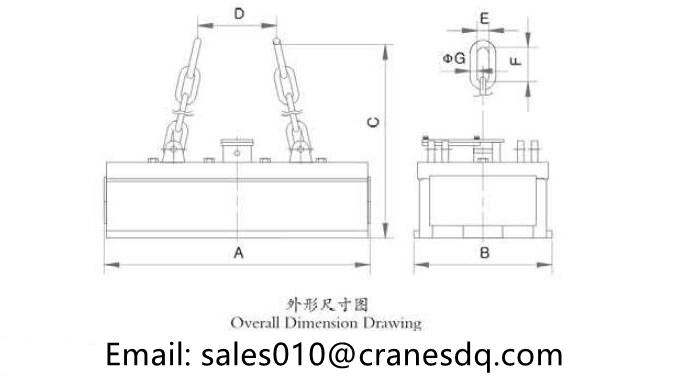

MW22 Series Lifting Electromagnet

The most widely used series whose shape is rectangle especially suitable for lifting and transporting billet, steel ingot, bloom etc., also used for round, profiled steel as well. Different magnetic circuits are designed for different steels.

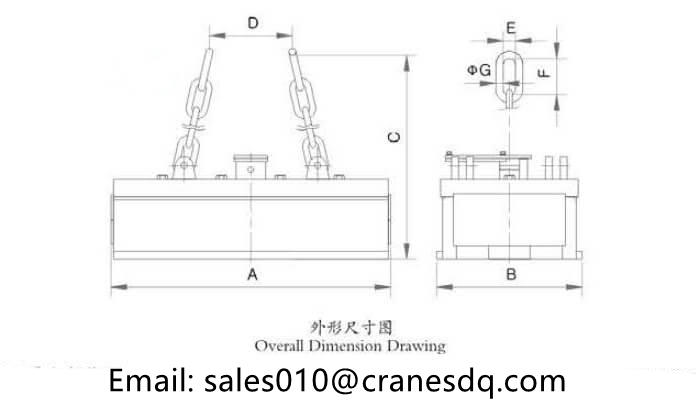

MW42 Series Lifting Electromagnet

MW42 super force series lifting electromagnet can generate powerful attraction force in attached area, which can be used for lifting and transporting billets, girder beam and track beam, and also used for lifting and transporting round billet and profile steel.

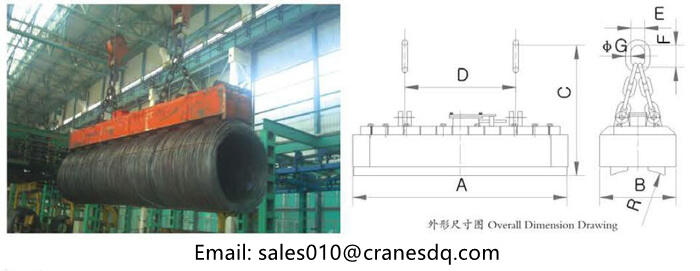

MW19 Series Lifting Electromagnet

MW19 series lifting electromagnet, owing to light self-weight, reasonable structure (just contact with two points of the bar) is suitable for coiled bar. Its magnetic pole is suitable for different diameter coiled bar. The length of coiled bar is important in choosing the right electromagnet. It can be put into operation along length or width direction of electromagnet and multiple units can be used together or separately as well.

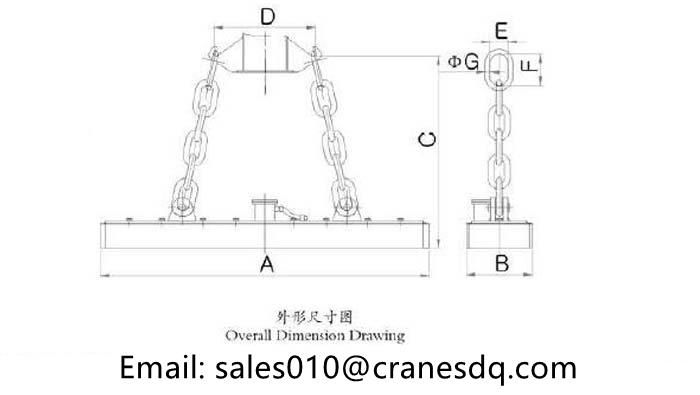

MW38 Series Lifting Electromagnet

MW38 series lifting electromagnet adopts unique magnetic circuit which has good advantages in heat dispersion, penetration (for example it can penetrate air gap through multiple layers). It can lift and transport bar material, flat iron and angle iron in unpacked or simple packed situation. It also improves problem like big deflection when lift round steel and thread steel. There are two normal and high temperature type. Normally multiple units are used in operation, so two or four connection points are used for linking hanging beam. We made an example of two connection points linking way in this catalog.

MW35 Series Lifting Electromagnet

MW35 series lifting electromagnet whose magnetic circuit is designed specially and has deep penetration is mainly used for lifting and transporting round billet and steel pipe, square billet, steel ingot, cogged ingot and profiled steel.

MW85 Series Lifting Electromagnet

MW85 series lifting electromagnet design with unique magnetic circuit which has round arc pole for lifting and transporting steel tubes. Compared with other lifting tools like hook or steel wire, it can touch the tube right from the top and be able to load and unload the materials directly, thus it improves working efficiency greatly. At the same time, it will not touch neighboring tube provides a safety operation and energy-saving.

MW17 Series Lifting Electromagnet

MW17 series lifting electromagnet is specially used for lifting and transporting heavy rail. As the heavy rail has become super-long and super-heavy today with the rapid development of railway construction. We took note at some important heavy rail projects in order to provide ideal product for users. The products have been used at professional heavy rail manufacturing factories and large railway track beam factories.

This series adopt special magnetic circuit and double wrapping structure which has good property of heat dispersion and deep penetration. It can be used to lift and transport heavy rail, profiled steel and beam blank. It has normal and high temperature type. Normally it adopts multiple units.

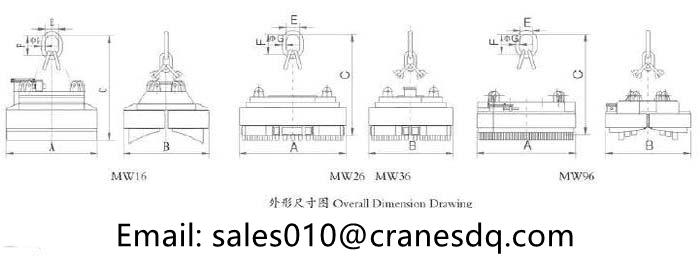

Lifting Electromagnet for lifting and transporting steel plate

This series is specially designed for lifting and transporting medium-thick steel plate. The whole operation is safe, exact and quick. When transport some long plates, they easily go distortion, so we suggest combination of multiple units to be used. For some plate which thickness is around the range of 6mm~32MM, space between 2 magnets should leave an extra 2.5~3.5m, the length at each end is that of one half of space. According to different lifting pieces, the series is divided into type 350 and type 400 and type 500 and type 650.

Type 350 is suitable for medium-thick plate factory, ship building factory, machinery manufacturing factory. It is controlled by adjustable magnetic field, and it can lift one or certain pieces of plates. Type 400 is suitable for lifting as many as possible pieces at a time. We can also produce the product less than 700℃(high temperature type)for you.

Lifting Electromagnet for Coiled Steel

This series lifting electromagnet is used for coiled steel. It has three types: vertical type, horizontal type and general type which can lift material both vertically and horizontally. High temperature type lifting electromagnet can be used at anneal process and can lift material vertically or horizontally at high temperature range from 100℃ to 600℃.Vertical type-magnet attracts its end face, suitable for coiled steel bundled or unbundled.Horizontal type-magnet attracts its side face, suitable for bundled coiled steel.

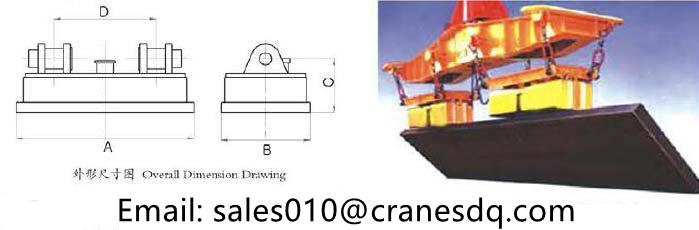

Lifting Electromagnet for Turning and Side Hung

This lifting electromagnet is suitable for turning slab up and down of checking and surface finishing, it can also apply to lift and transport thick plate and tube blank. It can turn slab around 180°degree when being lift by the crane equipped with guide column.

How to customize electromagnetic crane

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a electromagnetic crane, you can leave a message on the website or email, tell us the following information, and our sales manager will contact you:

- Lifting capacity (ton): __ ?( The rated capacity)

- Lifting height (m):__ ? (Height from hook center to the floor)

- Span (m): __ ? (Distance between rail center)

- Lifting speed (m/min): __ ? ( Single, Dual, Variable)

- Traveling distance (m): __ ? (The length of the rail)

- Work duty: __ ? (How many hours a day? How many times an hour?)

- What material to be lifted: __ ?

- Industrial voltage: __ ? ( like :380V, 50Hz, 3ph )

没有评论:

发表评论