3 components in the structure of electric chain hoist:

components in the structure of electric chain hoist

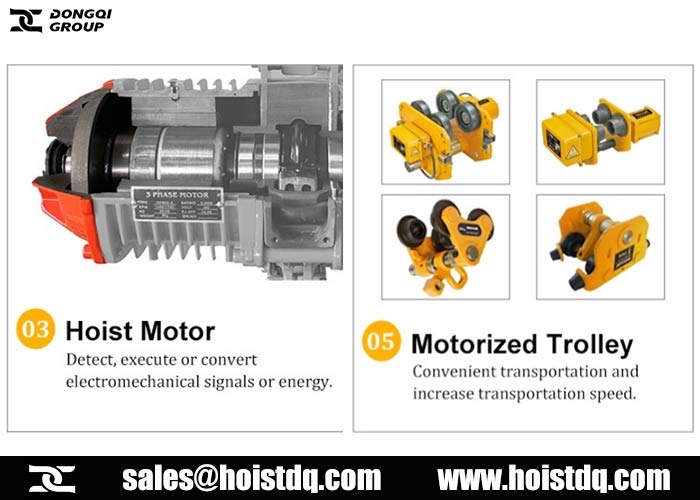

Motor

- The motor is the “heart” of the electric chain hoist and its source of power.

- The improvement of the level of motor manufacturing is the basis for the improvement of the performance of the electric hoist.

- With the development of technology, the overall performance of the motor is getting better and better.

- The new generation of motors widely adopts cylindrical Shaped flat disc brake motor, the shell is made of die-cast aluminum material, which is durable, good heat dissipation performance and small specific gravity, and superior performance.

Reducer

- The reducer of the electric chain block mainly relies on gears, and the gear materials used in the new generation of products are mostly processed by carburizing, quenching, gear grinding and other processes, which have good hardness, strong heat dissipation, wear resistance, impact resistance, and corrosion resistance.

- One of the basic ways to realize the load-carrying capacity of the electric hoist and prolong the service life of the electric hoist, and the reducer box material is die-cast aluminum or precision cast steel, which can realize seamless connection with the shell.

Trolley

- The new generation of electric hoist operating trolley adopts side layout, mainly to increase the effective lifting height, and then realize cost savings.

- On the basis of side layout, the combined anti-roller can balance the weight and load of the lifting mechanism.

- The material of the running trolley is generally made of alloy steel or ductile iron, and the traveling mechanism is basically horizontal wheel-oriented.

- This is because the wheels of the running trolley will have film material with the track during most of the travel, and the wear at the edge is often large, and the horizontal wheel is used. It can reduce driving resistance, thereby reducing wear and extending track life.

没有评论:

发表评论