According to different standards, crane service can be divided into different classifications. Usually, the most frequently used standards are ASME, CMAA, HMI, ISO, CEN EN, FEM and OSHA. In the following paragraph, it will put in length on crane service classifications based on CMAA (Crane Manufacturers Association of America), HMI (Hoist Manufacturer’s Institute), FEM (Federation Europeenne de la Manutention), and AISE Crane Service Classifications, and their comparisons for your sake to select the proper crane machine for your application.

CMAA crane service classifications

CMAA classifies crane services into six classes: A, B, C, D, E, and F, shown in the following paragraphs:

Class A Infrequent Service

Crane comes into class A has the features:

- Handling loads at slow speeds with long die periods between lifting.

- Capacity loads may be handled for equipment installation or maintenance.

- Applications: powerhouse, public utilities, turbine rooms, transformer stations, motor rooms.

Class B Light Service

Crane comes into class B has the features:

- Dealing light loads from no loads to full rated loads occasionally with slow speed.

- 2 or 5 lifts per hour, around 10 feet per lift on average.

- Application: Light assembly operations, service buildings, light warehousing, etc.

Class C Moderate Service

- Crane comes into class C has the features:

- Dealing loads with no heavier than 50 percent of the rated capacity on average

- 5 to 10 lifts per hour, around 15 feet.

- Applications: machine shops, paper mill machine rooms, etc.

Class D Heavy Service

Crane comes into class D has the features:

- Dealing loads around 50 % but of the rated capacity constantly,

- High working speed, 10 to 20 lifts per hour around 15 feet.

- Applications: Heavy machine shops, foundries, fabricating, plants, steel warehouses, container yards, lumber mill, etc.

Class E Severe Service

Crane comes into class E has the features:

- Handling loads around rated capacity throughout its life time.

- 20 and more lifts per hour at or near the rated capacity.

- Application: Cranes with magnet, bucket loading devices are used in scrap yards, cement mills, lumber mills, fertilizer plants, container handling, etc.

Class F Continuous Servers Service

Crane comes into class F has the features:

- Handling loads around rated capacity under severe service conditions throughout its life.

- Special care to maintenance is required.

FEM crane service classifications

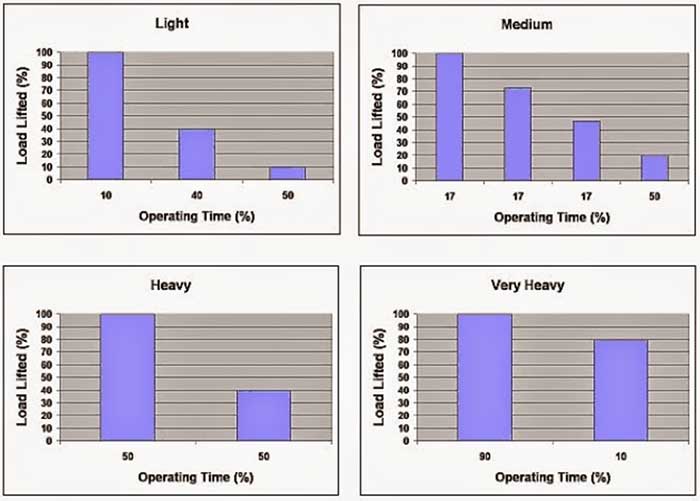

According to FEM standards, crane services can be grouped in the classes of Light, Medium, Heavy, and Very Heavy.

Factors determines the crane services group based on FEM standards are:

1. Load spectrum, which presents the frequency of loads with maximum and smaller lifting capacity during examined time.

2. Number of hoisting cycles during the lifetime of crane.

Example of different load spectrums:

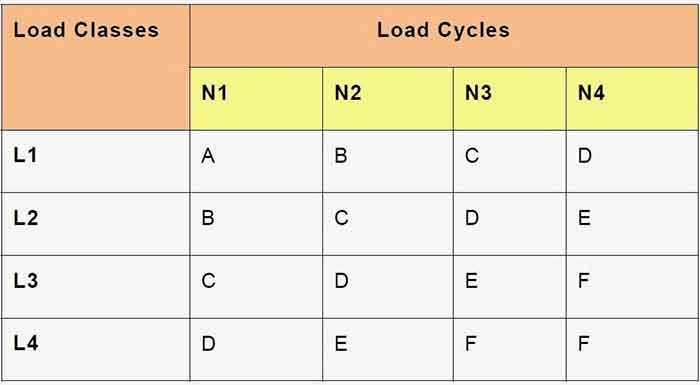

AISE crane service classifications

AISE also gives its method to calculate the crane services class, which is generally described in as follows:

- Crane Service Class 1 (N1): Less than 100,000 cycles

- Crane Service Class 2 (N2): 100,000 to 500,000 cycles

- Crane Service Class 3 (N3): 500,000 to 2,000,000 cycles

- Crane Service Class 4 (N4): Over 2,000,000 cycles

Further AISE describe the different Load Classes as:

- L1= Crane hoists light loads normally but rated load occasionally.

- L2= Crane hoists loads about 1/3 crane rated loads capacity normally but rated loads rarely.

- L3= Crane hoists loads between 1/2 and 2/3 of crane rated capacity normally but rate loads fair frequently.

- L4= Crane hoists loads with lifting capacity regularly.

The crane services class of a crane is determined as the following diagram based on the above load classes and load cycles.

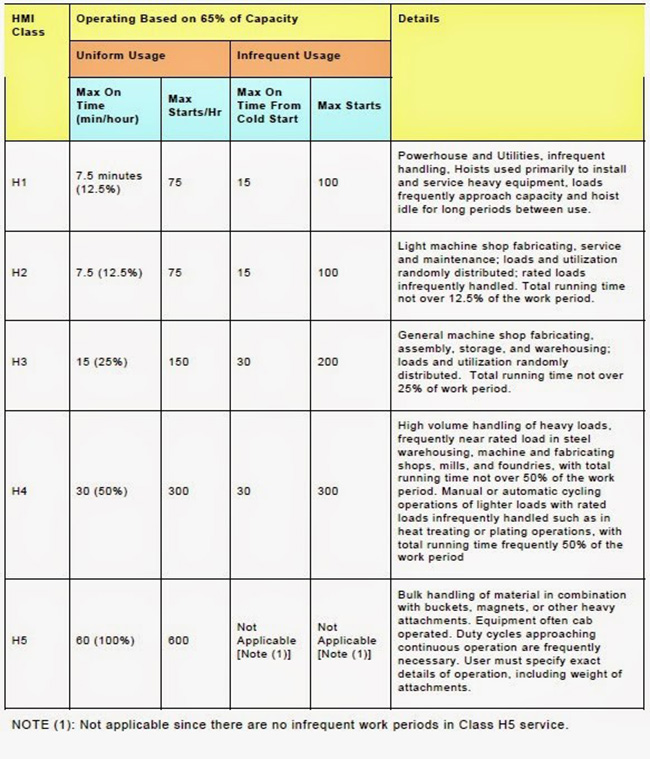

HMI hoist service classifications

HMI also provides a method based on the relative significance of duty cycle ratings for different types of electric hoists. HMI hoist service classifications is provided in the following table:

![]()

Note: It requires various additional information of the hoist application conditions to determine the duty cycle.

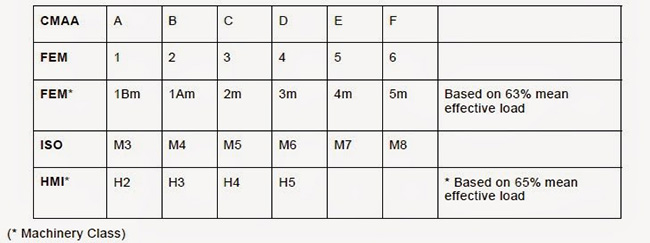

Comparison of different Crane service classifications

Different crane service classifications are given based on different standards. In order to give you a better understanding to the different crane service classifications, the comparison on CMAA, FEM, ISO, and HMI crane service classification are shown in the following table:

Conclusion

Various crane service classifications based on different standards are various ways to help you to select the proper crane or hoist for you application. Do remember when choose the crane or hoist for your application, you have to consider the following factors which need to confirm with your crane or hoist manufacturer:

- Hourly lifts and trolley and bridge movements on average.

- Length of each movement on average.

- Estimated weight of loads required to be lifted each time on average.

- Total operating time per day.