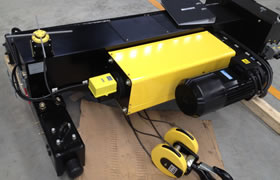

As a kind of lifting equipment, gantry Crane factory are widely used in many industries. Due to its wide use, in order to ensure the safe operation of the operation, we will have a series of requirements and attentions when using it. This is both for gantry cranes. Can play a very good protection, but also can extend its service life. So for newly purchased gantry cranes, the most qualified installers will generally be asked to perform trial operation, and then run-in when it can work normally.

The work of the newly purchased gantry crane is as follows:

1. Since the crane is a special equipment, the operator should accept the manufacturer’s training, guidance, structure and machine performance to have a comprehensive understanding, and obtain certain operation and maintenance experience, and be able to operate the machine. The product use and maintenance instructions provided by the manufacturer are the basic information for the operators who operate the equipment. Before operating the machine, please read the instructions for use and maintenance, operation and maintenance according to the requirements of the instructions.

2. Pay attention to frequently observe the indication of the instrument. If there is an abnormality, stop the loss in time to eliminate the cause of failure and the failure has not been eliminated. Stop the operation.

3. Pay attention to the work load during the operation period. The work load cycle operation generally does not exceed 80% of the rated load, and the workload should be arranged to prevent the machine from overheating time due to continuous operation for a long time.

4. Pay attention to frequently check the lubricating oil, hydraulic oil, coolant, brake fluid and fuel oil (water) and quality, and pay attention to check the sealing of the machine. The inspection found that due to the lack of excessive oil and water, the reasons were analyzed. At the same time, it is necessary to strengthen the lubrication and recommendations of all lubrication points during operation. Each category has lubricating point grease (except for special requirements).

5. Keep the machine clean, adjust in time, and tighten loose parts to prevent loosening, aggravating the wear of the parts or causing the loss of the parts.

6. After the cycle operation is over, the machine should be maintained compulsorily, check and adjust well, and pay attention to changing the oil.

The above are the precautions after purchasing a new gantry crane. Doing these details is conducive to the later use of the gantry crane, and it also allows it to be used for a longer period of time.