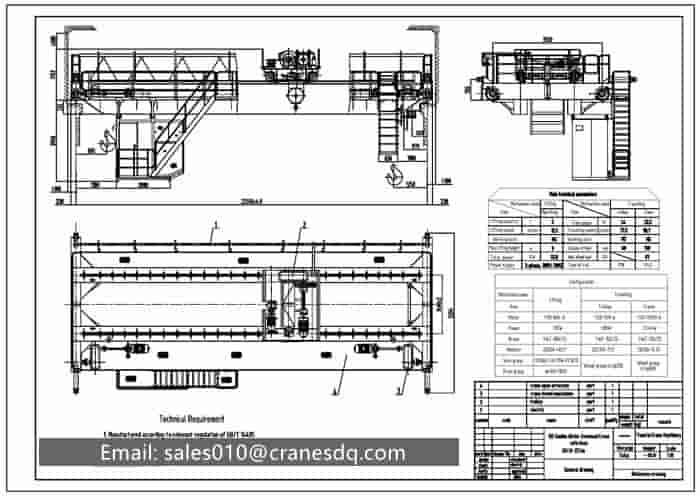

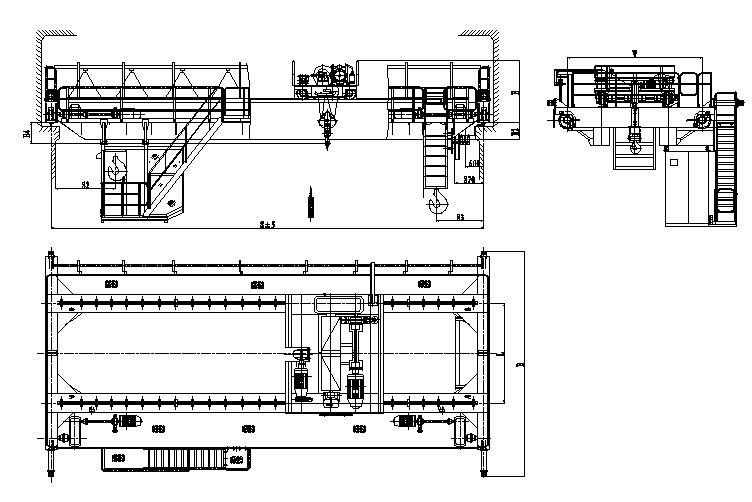

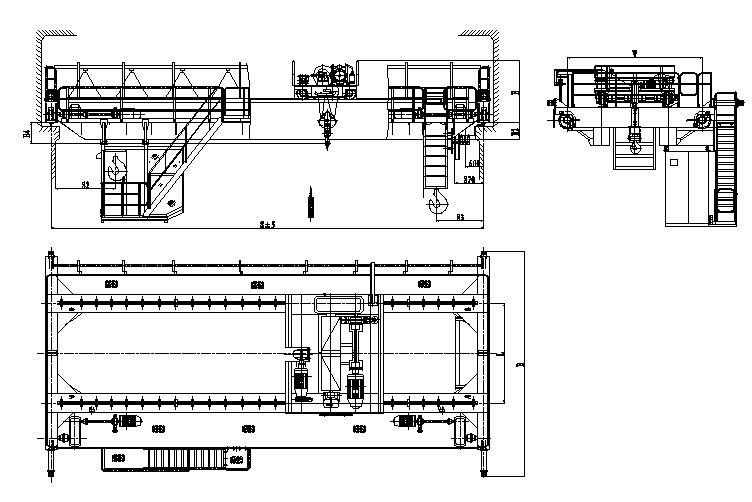

Main structure and characteristics of overhead crane

It is mainly composed of bridge, trolley, crane operating mechanism and electrical

The lifting mechanism, trolley operating mechanism and crane operating mechanism are the three working mechanisms of the crane. Each mechanism is equipped with a separate motor for their own drive.

The crane with lifting capacity of 5 and 10 tons is a single hook crane with only one set of lifting mechanism.

16 / 3.2 ~ 50 / 10 ton cranes have two hooks, so there are two sets of independent lifting mechanisms, main and auxiliary.

The main hook is used to lift heavy objects. In addition to lifting lighter objects, the auxiliary hook can also be used to cooperate with the main hook to tilt or overturn workpieces within its rated load range.

However, it must be noted that two hooks are not allowed to lift two objects at the same time. When the two hooks work together, the weight of the object shall not exceed the rated lifting capacity of the main hook.

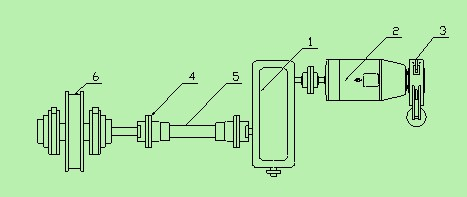

Lifting mechanism of overhead crane

- Single hook is a set of independent driving device. When there are two main and auxiliary hooks, two sets of lifting mechanisms driven independently are installed.

- The lifting mechanism is driven by the high-speed rotation of the special motor for YZR crane and the involute gear reducer is driven by the gear coupling. The low-speed shaft of the reducer rotates the drum wound with steel wire rope. As long as the motor and forward and reverse rotation are controlled, the lifting function of the hook can be achieved.

- In order to ensure the safety and reliability of the lifting mechanism, a brake is installed on the high-speed shaft of the reducer. An overload limiter is installed on the bearing seat at one end of the supporting drum to prevent overload of the lifting load. Its mechanical composition is as follows:

- Main overload limiter;

- Main lifting motor;

- Main lifting gear coupling;

- Main hoisting drum

- Main hoisting brake wheel coupling;

- Main lifting brake;

- Main lifting reducer

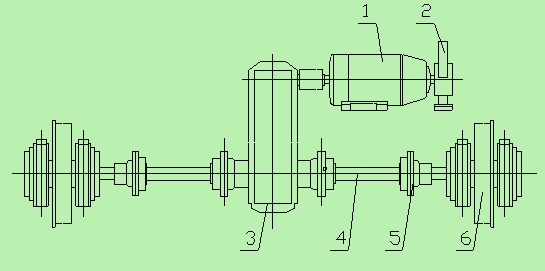

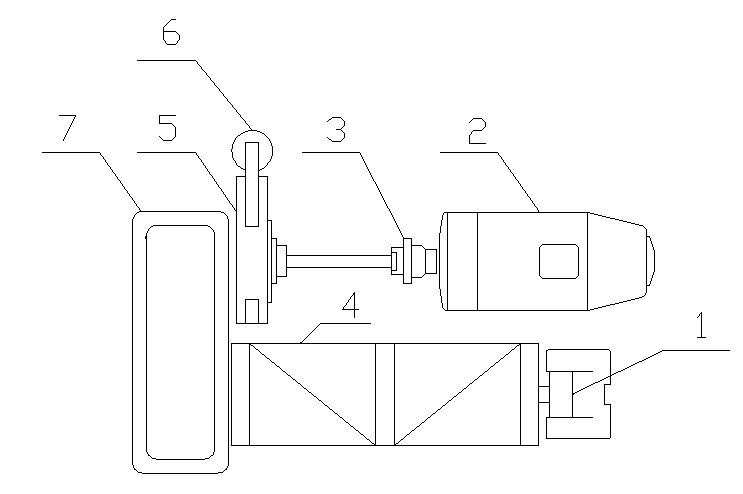

Trolley running mechanism of overhead crane

1. The trolley running mechanism is a vertical involute gear reducer driven by a motor. The low-speed shaft of the reducer is connected to the driving wheel mounted on the trolley in a centralized driving manner. The motor adopts a double end output shaft, and one end of the shaft is equipped with a brake.

2. The crane trolley has four wheels, which are installed at the bottom of the trolley. Two of them are active wheels and the other is passive wheels. The driving device is composed of 1. Motor, 2. Brake, 3. Reducer, 4. Compensation shaft, 5. Coupling, 6. Wheel, etc. the machine composition is as follows:

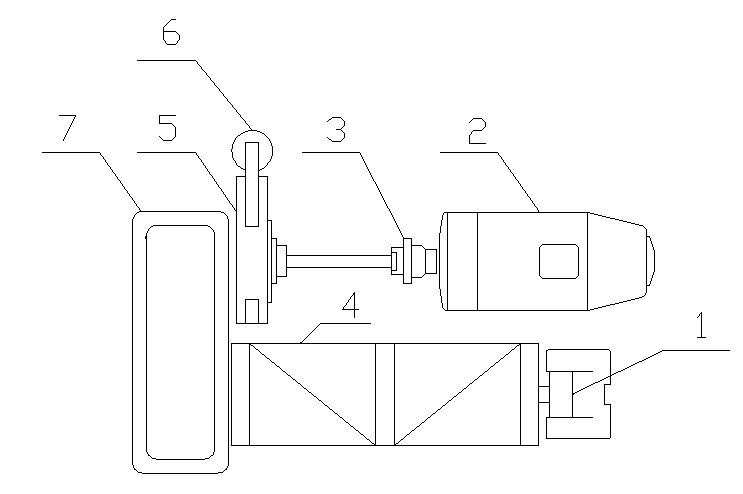

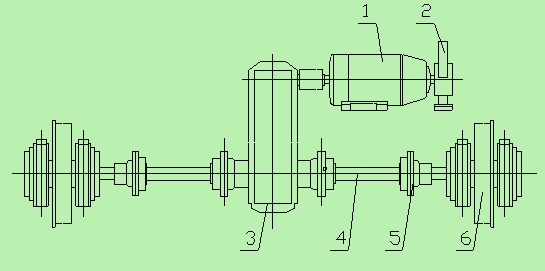

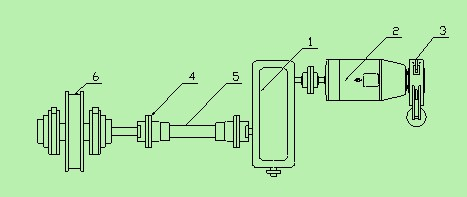

Crane operating mechanism of overhead crane

1. The crane has four traveling wheels, which are installed at both ends of two end beams. Two of them are active wheels and two are passive wheels. The driving mechanism of the driving wheel is installed on the walking platform. Here, two sets of symmetrical independent driving devices are used, which we call separate driving.

2. The reducer adopts circular arc gear reducer with higher load capacity than the same type of involute tooth profile. All mechanisms adopt rolling bearings and AC electromagnetic iron block brakes.

3. The driving device is composed of 1. Reducer, 2. Motor, 3. Brake, 4. Coupling, 5. Compensation shaft, 6. Wheel, etc. its structural diagram is as follows:

4. All mechanism components are connected by gear coupling. In this way, even the errors generated during manufacturing and installation, or the displacement between components caused by bridge deformation caused by load, can be compensated by the gear coupling without affecting the work of the mechanism.

5. Both active and passive wheel axles are supported on the angular bearing housing, so the structure is convenient for assembly, disassembly and maintenance.

Working principle of overhead crane

Driving method of moving mechanism of overhead crane can be divided into two types: one is centralized driving, that is, one motor drive long transmission shaft to drive active wheels on both sides; the other is separately driving, that is, active wheels on both sides are driven by one motor. Middle and small overhead cranes always adopt brake, reducer and motor to combine into “three-in-one” driving method. In order to install and adjust, most of overhead crane in heavy-duty always adopt universal coupling as its driving device.

As for moving mechanism of overhead crane, to increase wheels can be used to decrease wheel pressure if the lifting capacity is too large. If the amount of wheels exceed four, it had better adopt device to balance bogie to keep the loads of overhead crane can be distributed to every wheels.

Metal structure of overhead crane is composed of main beam and end beam, which can be divided into two categories: LD single girder overhead crane and QD double girder overhead crane. LD single girder overhead crane is composed of one main girder and both end beams, QD overhead crane is composed of two main girders and two end beams.

Main girder and end girder are in rigid connection, both ends of end girders are designed with wheels to support the overhead crane moving in the elevated track. There are traveling track welded to support the moving of lifting trolley.

Composition and working principle of overhead crane