The winch completes the traction drive with human power or mechanical power driving a reel. It can vertically lift or horizontally and obliquely draw heavy weights.

An electric winch consists of a motor, the coupling, the brake, the gear bos, and the reel which are altogether installed on the machine frame. For high lifting height, heavy load and unload as well as frequent work, the winch has a good speed regulation making a empty hook swiftly down, and for installed or sensitive material, the winch can adopt a small speed.

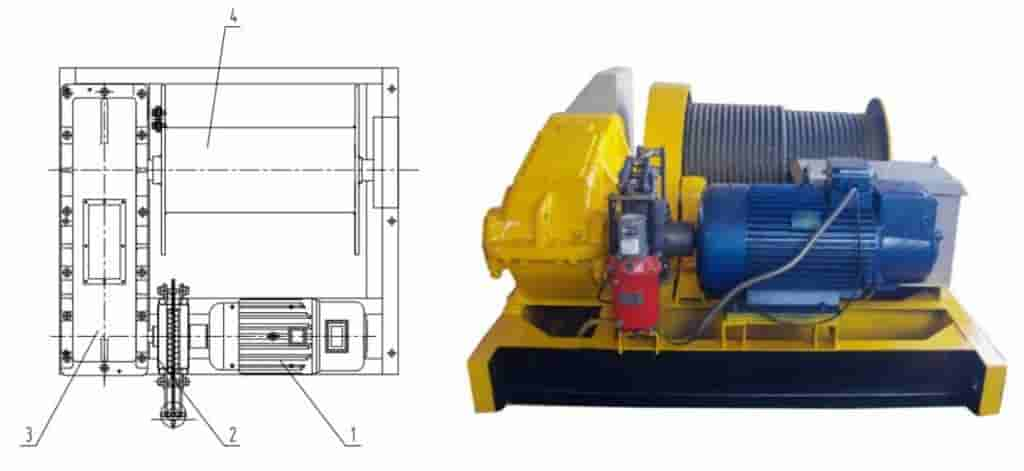

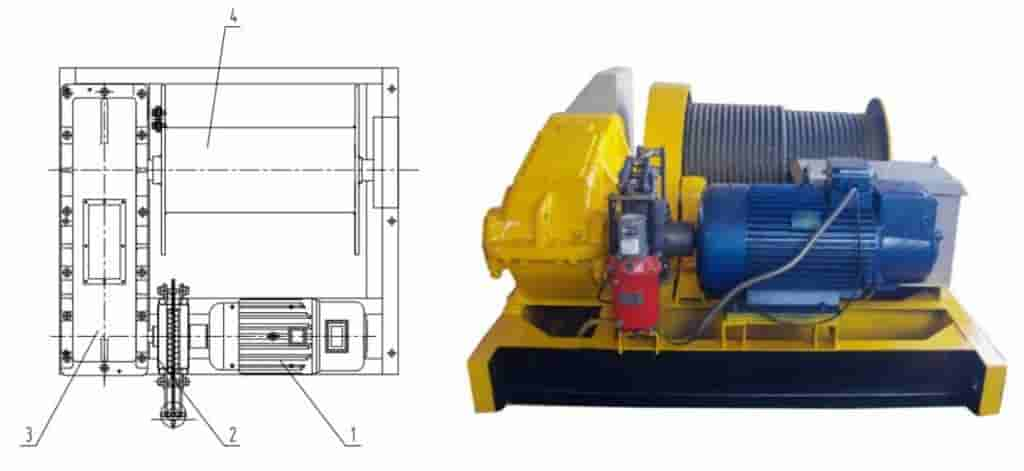

How the winch works

The winch transforms electric energy into mechanical energy through the motor1, which is rotor of the motor moves, outputs, and then through the brake 2, and the reducer 3 reduces speed to rotate the reel 4. The reel winds the wire rope and passes through pulley block to make the hook lift the load Q, and transforms mechanical energy into mechanical work finishing transportation, load and unload of heavy weights.

Classification and characteristics of Dongqi hoisting winches

There are JM series electronic control slow speed winch, JK electronic control high speed winch, JMM friction series winch, JK-D series winch and IKL series hand control high speed free rolling winch.

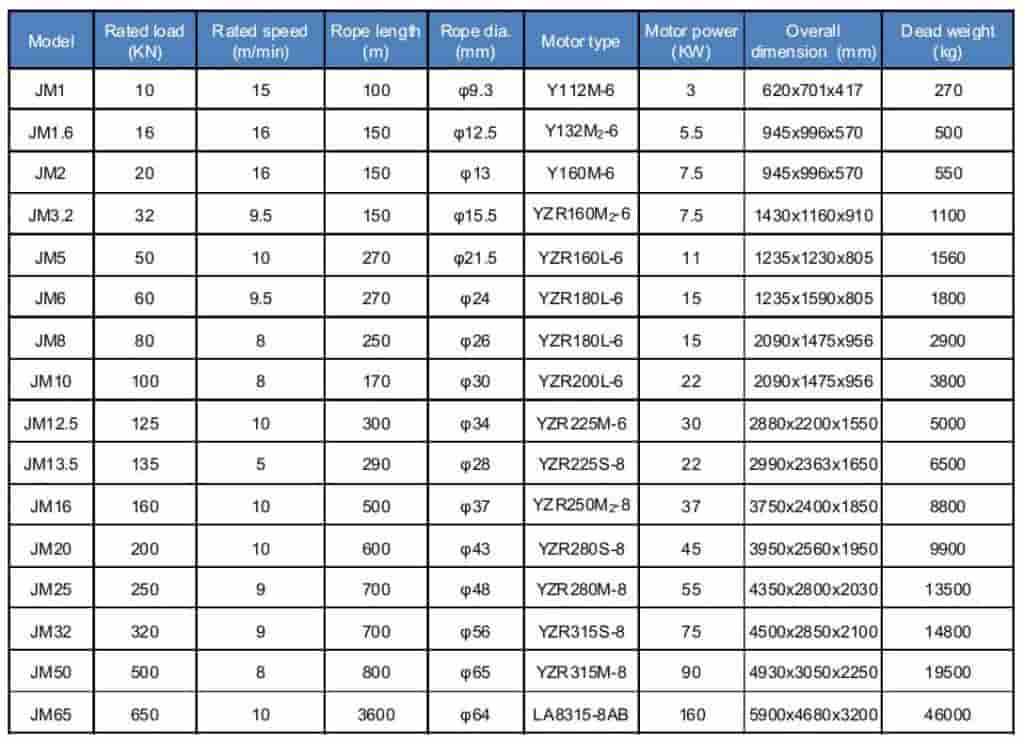

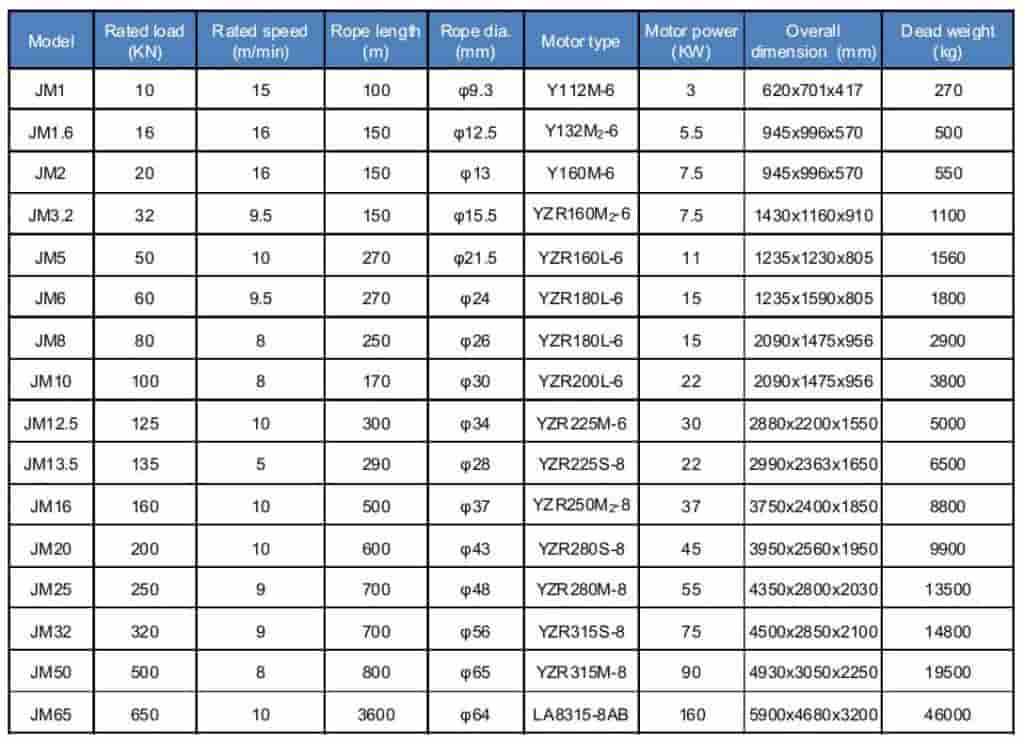

JM series

The winch below 10t is mainly used for hoisting, pulling and loading as well as drawing heavy weights. It is also used for all kinds of large and middle concrete constructure of steel, installation, and disassembly of mechanical equipment. It is suitable for construction and installation companies, mineral zone and plant. The winch equal or above 10t is mostly used for large and oversize concrete constructure of steel installation and disassembly of mechanical equipment. Orderly arrangement of the wire rope and safe lifting makes it suitable for kinds of bridge engineering, large factories, mine engineering equipment installation.

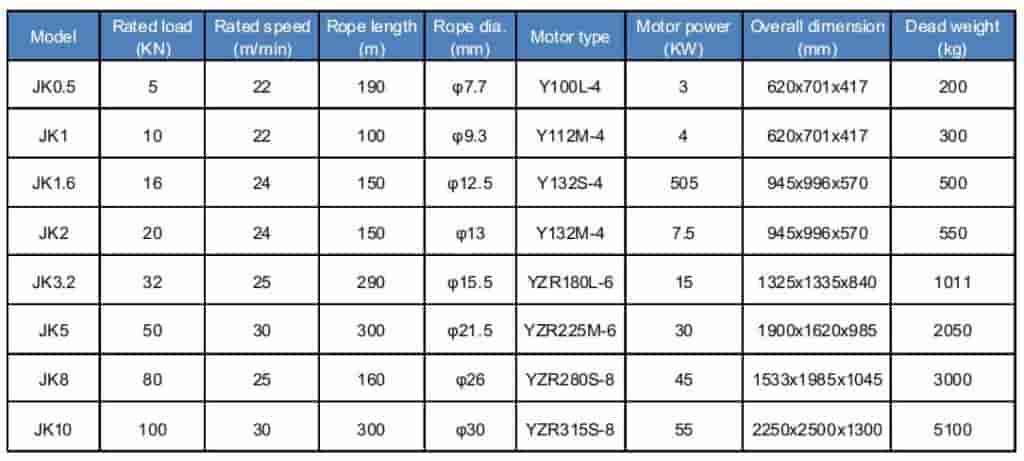

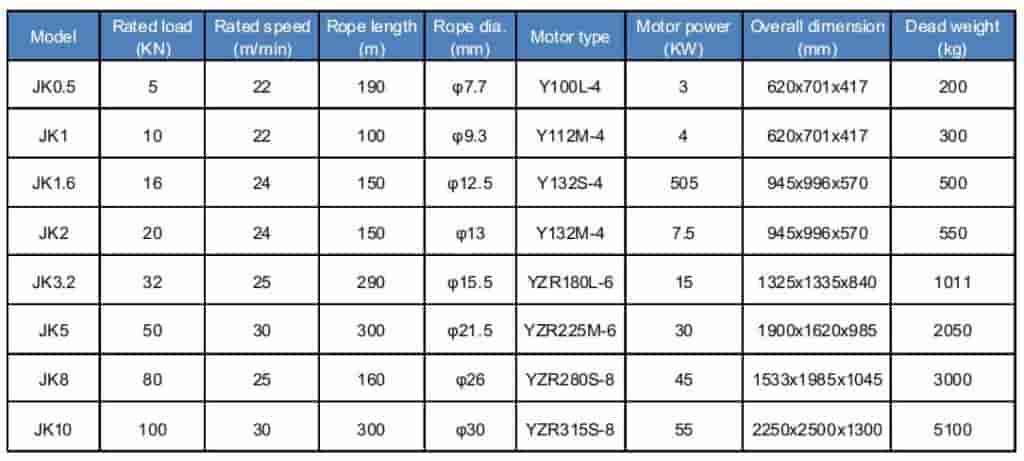

JK series

The winch below 10t is mainly used for hoisting, pulling and loading as well as drawing heavy weights. It is also used for all kinds of large and middle concrete constructure of steel, installation, and disassembly of mechanical equipment. It is suitable for construction and installation companies, mineral zone and plant. The winch equal or above 10t is mostly used for large and oversize concrete constructure of steel installation and disassembly of mechanical equipment. Orderly arrangement of the wire rope and safe lifting makes it suitable for kinds of bridge engineering, large factories, mine engineering equipment installation. the winch is mainly used for material lifting, heavy weights traction. It is also used for crane as the main hoist. It is the special winch of derrick and gantry frame and lifting trolley. It is suitable for construction and small equipment installation of construction, mine and factory.

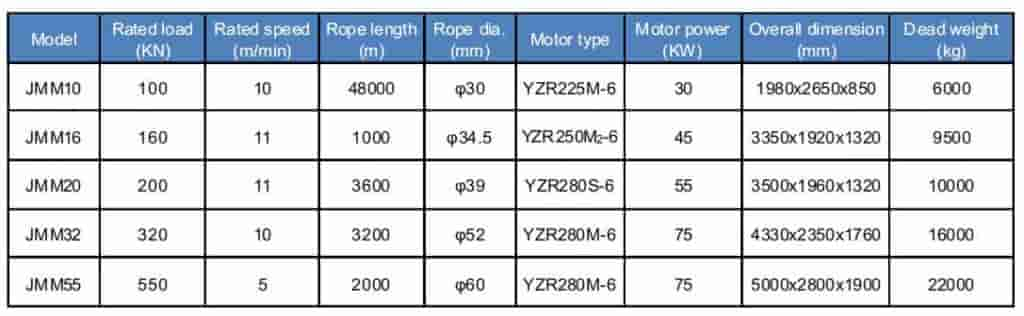

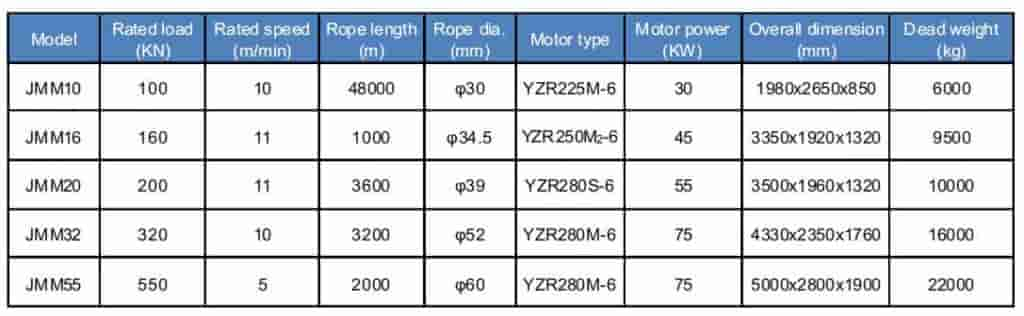

JMM series

The winch below 10t is mainly used for hoisting, pulling and loading as well as drawing heavy weights. It is also used for all kinds of large and middle concrete constructure of steel, installation, and disassembly of mechanical equipment. It is suitable for construction and installation companies, mineral zone and plant. The winch equal or above 10t is mostly used for large and oversize concrete constructure of steel installation and disassembly of mechanical equipment. Orderly arrangement of the wire rope and safe lifting makes it suitable for kinds of bridge engineering, large factories, mine engineering equipment installation. the winch is mainly used for material lifting, heavy weights traction. It is also used for crane as the main hoist. It is the special winch of derrick and gantry frame and lifting trolley. It is suitable for construction and small equipment installation of construction, mine and factory. The series winch is mainly used for long-distance traction of all kinds of large and super concrete and steel structure and steel cable as well as lift of large construction. Orderly arrangement of the wire rope and safe lifting makes it suitable for kinds of bridge engineering, large factories, mine engineering equipment installation.

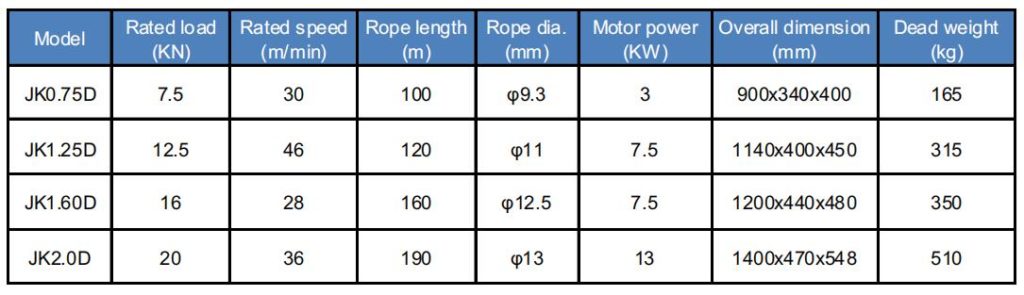

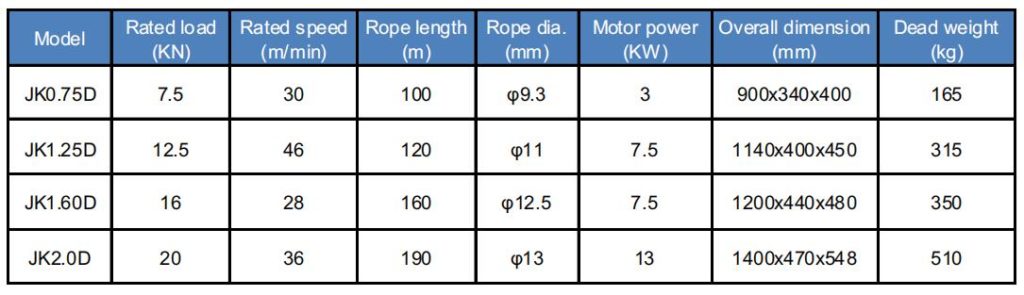

JK-D series

This winch, with small teeth difference, has compact and small structure, smooth running, convenient and easy maintenance, low noise and a long service life. It is widely used for construction,lift and installation of port, bridge and metallurgy

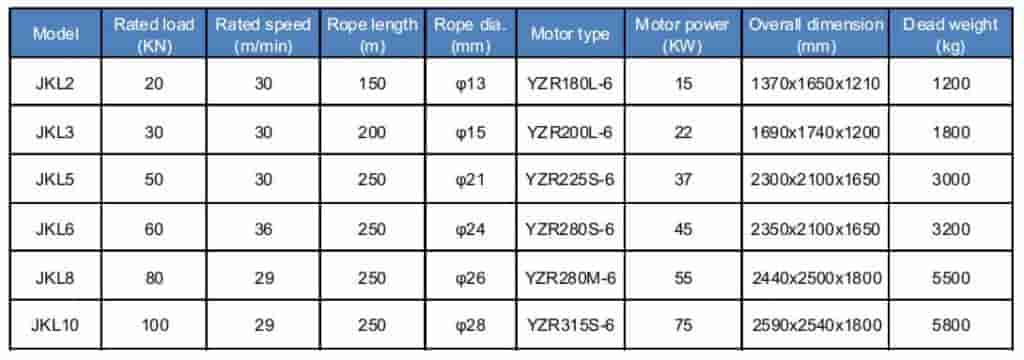

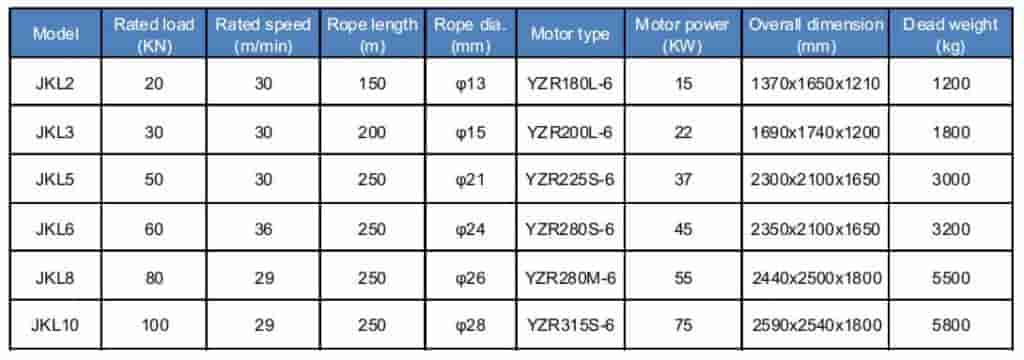

JKL series

This winch, with small teeth difference, has compact and small structure, smooth running, convenient and easy maintenance, low noise and a long service life. It is widely used for construction,lift and installation of port, bridge and metallurgy. This series of winch is mostly used for vertically lifting heavy weights in construction site, factories and mines,and ports, especially in bridge dock construction base engineering free-fall punching piling operation.

Dongqi winch parameters

Dongqi Lifting Winch PDF

https://www.craneyt.com/dongqi-hoist-design-and-manufacture-winch-specifications-and-pdf.html