Dongqi Crane Machinery is professional logistics handling products exporter, with long history trading time having rich technical experience. We are located in Changyuan— the crane’s hometown, have passed the ISO9001 quality system certification, ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification of enterprise, and CE certification. our products are recommend by WTO. Dongqi always adhere to customers first,holding positive attitude to satisfy the customers’ the demand.

Basic parameters of QG Overhead Crane with Carrier-beam

- Type: QG

- Lifting capacity: (5+5)t~(25+25)t

- Span: 10.5-31.5m

- Working class: A5,A6

- Temperature: -20~+40℃

Good quality, high production effeciency, few maintance;

High loading strength, high working class;

Flexible operation, safe and reliable.

There are two carrier-beam:

one is vertical to main girder, one is parallel to main girder.

You can choose you need.

QG Overhead Crane with Carrier-beam Features

(1) In General

- Good quality, high production effeciency, few maintance;

- High loading strength, high working class;

- Flexible operation, safe and reliable.

(2) Main Body

- Double girder, welding box beam, camber meet national standard;

- Adopt high quality carbon steel, Q235B or Q345B; (similar as Fe37 or Fe52);

- Main welding submerged are welded automaticly, nondestructive flaw detection;

- All metall materials(main girder,end girder, trolley)are chosed according to the national standard.

- Steel plate material requirements shot blasting before cutting, derusting grade reach Sa2.5 above.

(3) Crane and Trolley

- Crane protection grade is IP54 or IP44, F/H grade insulation

- Use special reducer, Hard-toothed surface, Reducer shaft inspected by Ultrasonic testing;

- Main hook’s reducer shell welding, taking a seal grooves, shaft top sealed well;

- Use YWZ model electric&hydraulic pushing rod often-close brake, the main lifting use double brake;

- Drum material is 16Mn, made of steel.drum shaft and cylinder body are welded and inspected by ultrasonic testing.

- The wheel tread are treated by heating processing;

- Pulley block are made of rolled steel;

- The tooth shape coupling, and the material of the 40 Cr, forging steel;

- All buffers use polyurethane (pu) type, on same span,

- Buffers must have same height;

- Hook use forged material, nondestructive flaw detection, fortify the slot device.

(4) Electric System

- All electric are SIMENS & SCHNEIDER;

- Crane can use safe slipping line to get power , slip line is located against the cab;

- Wire ropes are put in the steel trough or metal tube;

- On dangerous points equipped with protection device;

- The wire ropes are closed in hard steel tube or metal soft tube, line pipe and trough are welded on crane’s metall construction.

- Trolley’s cable devices are fixed inside of walking board;

- Bridge lighting use special crane damping lamps. Set special lighting circuit.

(5) Protection Devices

- The crane and trolley have travelling stop block, hook have double limiters,one of them is on drum

- Crane equipped with audible and visible alarm, and slipping line protection device prevents any danger to person;

- A cage is fixed on slip line side under the main girder,convenient to repair the slip line.

- All of the connection axis, floating shaft all has the shield to prevent danger.

- All doors on crane have interlock protection device, when the door is open,crane will stop travelling.

(6) Operation Device

- Ground control and cabin control;

- Special cabin for bridge crane or capsule driver room, open vision comfortable operation;

- The cable has open style, close style, can fixed on left or right;

- The open direction includes end open, side open or top open;

- The cabin has special small room and the capsule cabin;

- Ground control has handle and remote control; do not need to set up special driver;

- Users can choose as you need.

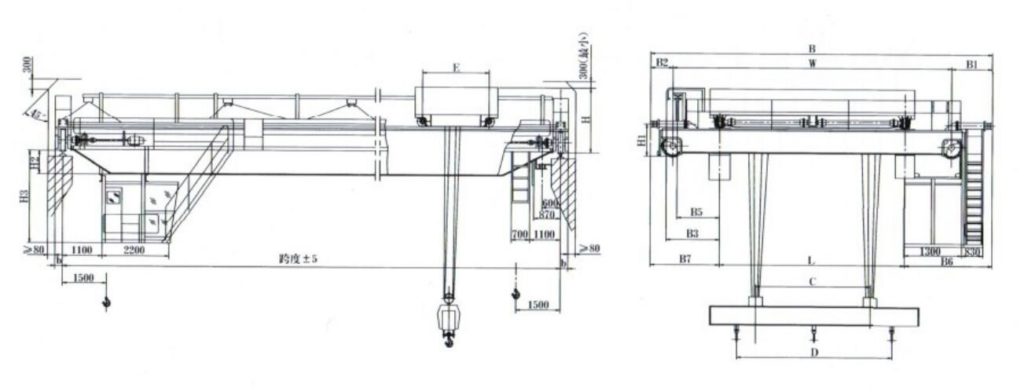

QG Overhead Crane with Carrier-beam Design Drawings

QG Overhead Crane with Carrier-beam PDF

https://www.craneyt.com/qg-overhead-crane-with-carrier-beam-specifications-and-pdf.html

没有评论:

发表评论