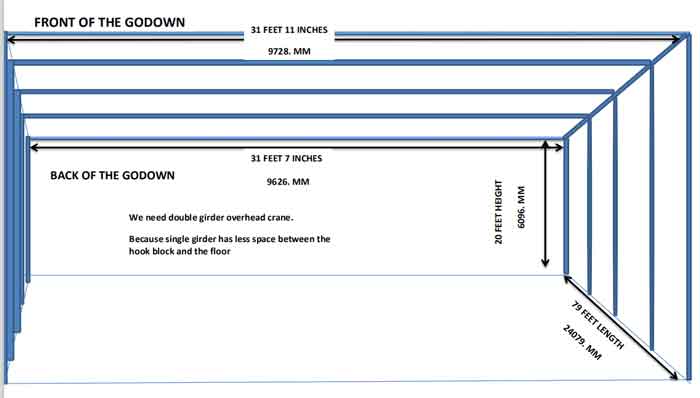

3 ton + 3 ton low headroom overhead crane for sale Maldives for material handling in Timber factory.3 ton overhead crane for limited space workshop.

Background of client

Maldives Client is in the field of wood and timber industry for more than 40 years, who has a good relationship with local government officials. The boss of the Maldive timber factory is the main contact person, around sixty, a nice gentile man, knowing exactly what he needs and a trustworthy businessman who will always keep his promises. It is very delightful to cooperate with him.

Timber workshop of Maldives client

Typical features of double girder overhead crane needed for the Maldives timber workshop

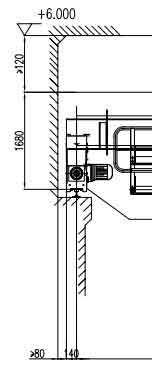

- Existing factory building -- with limited space, limited size and week supporting structure

- Span Maximize -- reduce column width

- Maximum lifting height -- the steel plate of the main beam is thickened, and the height is reduced

- End beam/ End carriages minimized -- European-style structure, compact layout

In a word - the 3 ton + 3 ton overhead crane needs to be designed with the smallest size or dimensions but at the same time have the largest working coverage in the workshop of timer factory with the features of limited space and relatively week supporting structure.

Timber workshop of Maldives client which needs the 3 ton + 3 ton overhead crane for material handling

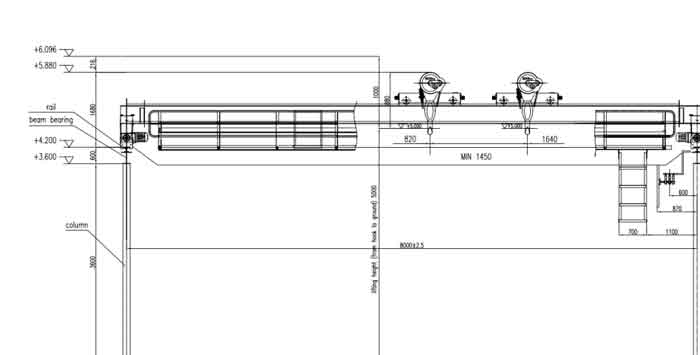

Initially design of the 3 ton + 3 ton double girder overhead crane

Initial 3 ton overhead crane design for the Maldives timber workshop

Initial 3 ton overhead crane design for the Maldives timber workshop Initial 3 ton overhead crane design for the Maldives timber workshop

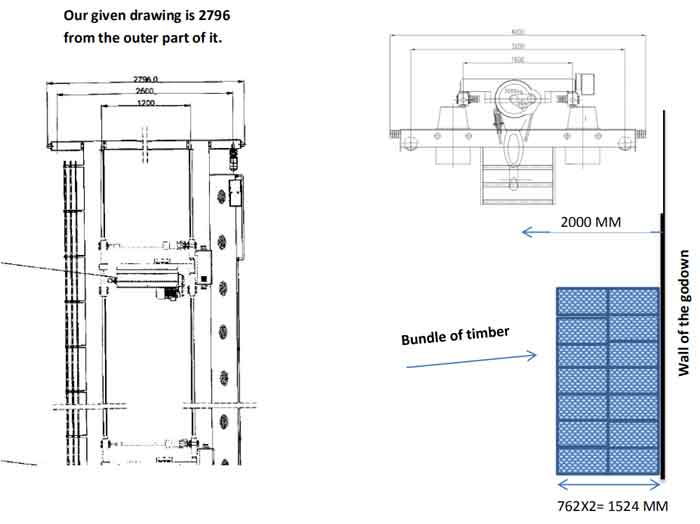

Initial 3 ton overhead crane design for the Maldives timber workshopInitially the span is designed based on the specification that the overall width is 1.5m

Second revision of 3 ton overhead crane design

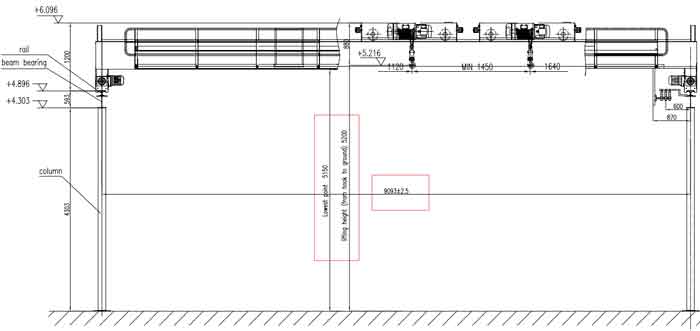

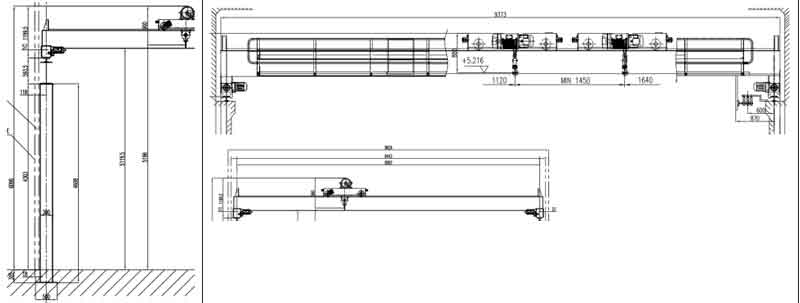

Modify the span and lift height of the 3 ton + 3 ton overhead crane according to the actual specifications of supporting column of the crane rail. The boss of the Maldive timber factory requires the the lifting height of the overhead crane, the distance from the lowest point of the main beam to the ground at least 5 meters

Second revision of 3 ton + 3 ton overhead crane design drawing

The end beam is 4 meters long which will result in two blind areas of at least two meters on both sides of the working area, and the length of which needs to be reduced as much as possible, at least 2796mm ( based on the designing of the Singapore supplier. )

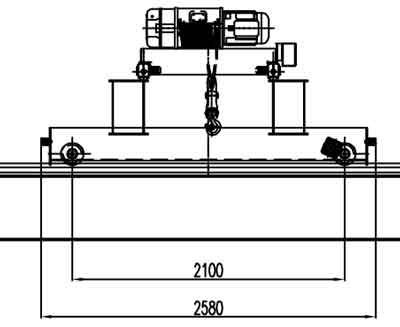

3 ton hoist trolley for timber handling overhead crane

3 ton hoist trolley for timber handling overhead crane 3 ton hoist trolley for timber handling overhead crane

3 ton hoist trolley for timber handling overhead crane

3 ton overhead crane for Maldives clients

The dimension should be clearly indicated on the drawing and the sizes of all parts should be labeled including the total height and total length.

The supporting structure of the workshop is strengthened and and at same time to ensure the working coverage is maximized.

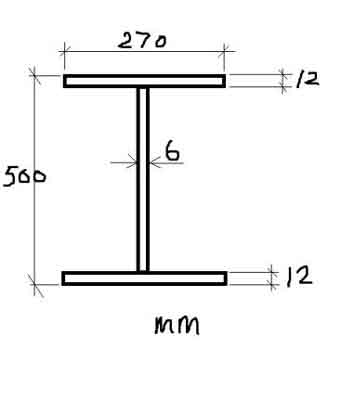

On rail beam specifications

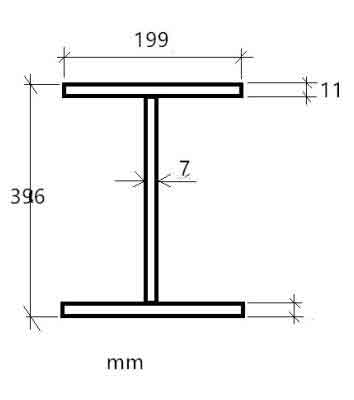

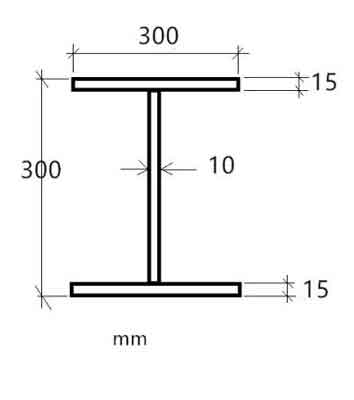

The specifications of H beams, shown as the following picture

Rail specifications

Rail specifications Rail specifications

Rail specifications Rail specifications

Rail specificationsAdjust the column layout

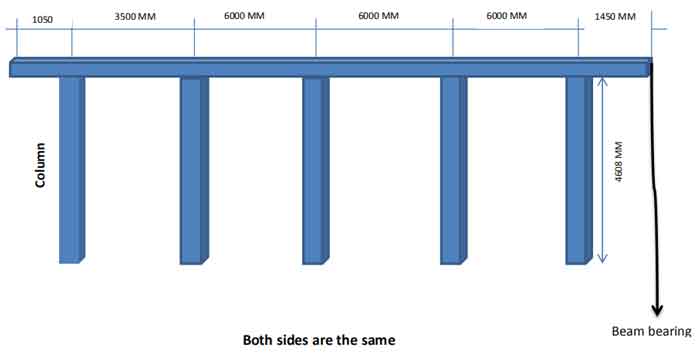

The column layout is adjusted for the boss needs cantilevers on both sides.

Colum design adjustment

Question: Is it possible to change the direction of the column at will? Answer: NO!

In fact, the change of the direction of the column has an impact on the load-bearing. It is necessary to increase the size of the column, and the price will increase a lot. ( It is acceptable when the price difference is within a reasonable range due to the steel thickness is increased, and more intuitively, steel weight is much heavier.)

HN396*199*7*11, 83kg/m

HW300*300*10*15, the rice weight is about 120kg

Please note that the extra height of the column will goes through the ground, so please do no think to fit the measurement.

The column is required to be increased in length of 4.303m--4.608m, and the excess part of 305mm is buried underground to ensure that the ground is flat.

没有评论:

发表评论