Custom Gantry Cranes Bring Efficiency to Modular Building Lines

Gantry crane requirement:

- The order is from a world leading manufacturer of commercial modular buildings manufacturing facility located in Pennsylvania.

- Recently the company shifted the construction of modular walls from lumber to steel. This shift required the creation of new production lines at their facility.

- Because of the tight spaces around the machinery, to look for an effective material handling solution, the general manager found us, DQCRANE.

Customized crane solution:

- After watching the video of the steel cutting application, our engineer reviewed the project and quickly developed a custom solution.

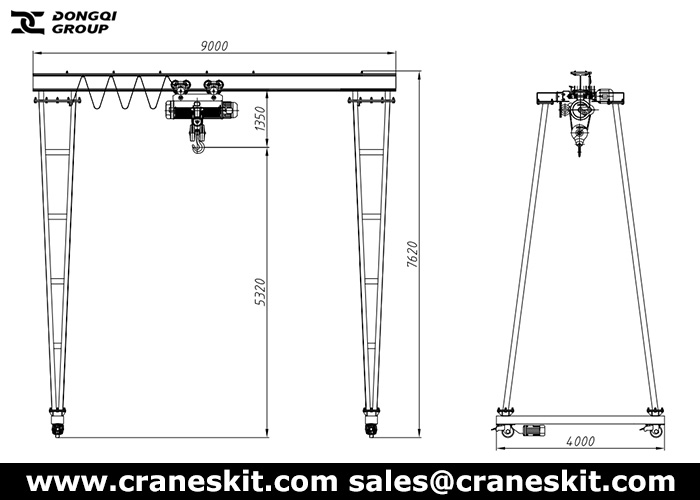

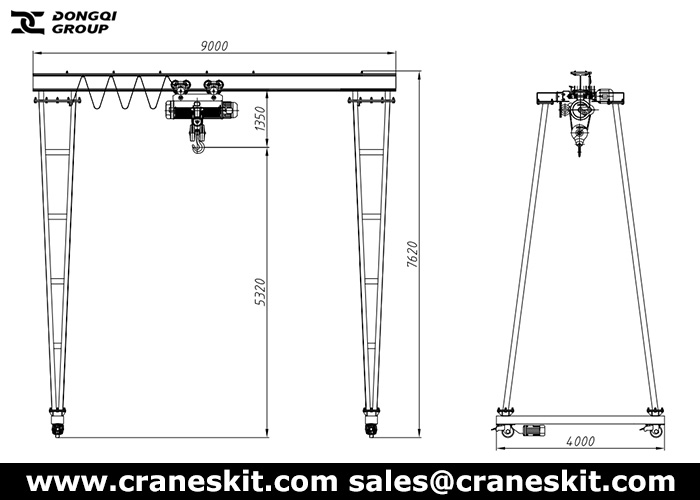

- Lifting capacity of this portable gantry crane is 10 ton, span 9m, lifting height 5.32m, and is power driven by motors on gantry legs.

- The crane operator uses a push button control pendant that is mounted on the side of the gantry to easily position the crane over the steel.

- The pendant also allows him to control 10-ton power driven wire rope hoist, to raise the steel bundle and the gantry is powered to move the load down the tracks towards a conveyer that feeds the ban saw.

Feedback:

DQCRANE crane machine custom portable gantry crane has greatly improved the safety and efficiency of their modular building production lines, our customer is very satisfied with our crane design solution.

没有评论:

发表评论