| Product Type: | Rail Mounted Container Gantry |

|---|---|

| Lifting Capacity: | 16 ton , 32 ton |

| Span: | 20~55m |

| Lifting Height: | 16m, 12.3m |

| Working Class: | A6, A7 |

| Ambient Temperature: | -20~40℃ |

Rail mounted container gantry cranes, often refereed as RMG crane for short, is a heavy duty portable gantry crane which are primarily used to load, unload, move, and stack containers in railway transshipment areas and large container storage yards. Therefore, they are also called rail mounted container gantry crane. Th rmg cranes are mian consisted of the main girder, rigid and flexible outriggers, trolley travel mechanism, lifting mechanism, crane travel mechanism, electric system, and operator’s driving cabin, etc.

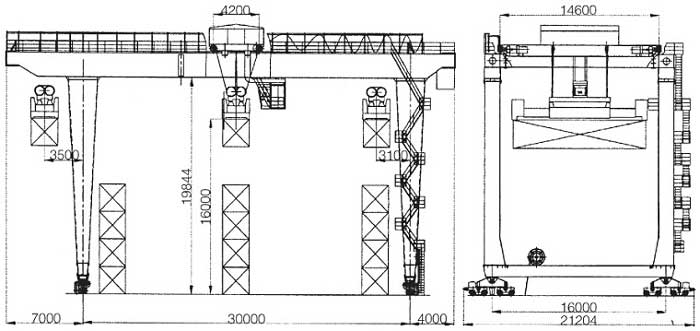

Crane drawing of rail mounted gantry crane

Applications of Rail Mounted Gantry Crane

RMG cranes are typically used for large container-handling, which are commonly found in intermodal and container terminals. The rail mounted stacking cranes has a high working level and a fast running speed, which provides exceptionally smooth operation and speeds up the turnover of the container carrier or other cranes. The best rmg crane system are available for your specific application based in order to maximize your material handling efficiency and safety.

Rail mounted gantry crane

Rail mounted gantry crane Double girder rail mounted gantry crane

Double girder rail mounted gantry craneFeatures of Rail Mounted Container Gantry Crane:

- Low lifting speed as a result of the low lifting height. High crane traveling speed meets the productivity requirements of long-track container storage yards. When the stack of containers is three or four layers, the spreader would go over the fourth/fifth container layer, and its lifting height would be determined by the storage yard's requirements.

- The speed of the trolley is determined by the span and the outreaching distance of both sides of the bridge. If the span and outreaching distance are short, a slower trolley traveling speed and higher productivity are recommended; otherwise, the trolley traveling speed could be increased to meet the productivity requirement.

- When the span exceeds 40 meters, the crane mechanism travels at a high speed, and both sides of the outriggers deviate due to the different drag on each side. As a result, this crane has a stabilizer, and the electric system keeps both sides of the traveling mechanisms synchronous.

- The electrical drive-control system uses a thyristor speed regulating drive AC or DC control system to meet the increased demand and achieve better speed regulating and control performance. Alternatively, it employs a conventional AC eddy current speed regulating control system as well as an AC stator voltage and speed regulating drive control system.

The electric control system of a high speed crane traveling mechanism is typically equipped with a thyristor speed regulating drive AC or DC control system or an AC stator voltage and speed regulating drive control system. Traditional AC eddy current speed regulating drive control systems that rely on brakes to shut down traveling mechanisms should be avoided in order to avoid a massive impact on the entire crane.

Main girder of rail gantry crane

Main girder of rail gantry crane Crane trolley for rail mounted gantry crane

Crane trolley for rail mounted gantry crane Rail gantry driving system

Rail gantry driving system Container spreader for rail mounted gantry crane

Container spreader for rail mounted gantry craneAdvantages of Rail Mounted Gantry Crane

The gantry crane is being used in many industries to reduce lifting and transferring times of heavy loads and to promote efficiency. It is appropriate for power plants, construction sites, ports, and rail terminals. There are numerous advantages to the rail mounted cranes that we manufacture.

- The rmg gantry crane is highly adaptable and can be used in a variety of working conditions.

- The container crane has a long service life and requires little upkeep.

- The crane gantry provides excellent performance and stable movement, with no sway during the operation of rail mounted stacking cranes.

- Our rail gantry crane has precise positioning and requires little setup time.

- Due to its low energy consumption, the rmg crane's operating costs are significantly reduced.

- When compared to other lifting systems, the continer gantry crane can significantly increase productivity.

Selecting The Right RMG Crane for Your Application

The intended gantry crane buyers are frequently unsure of which type of gantry crane is best for their operations. With so many different types of gantry cranes on the market, it is critical for customers to understand the differences and consider their own requirements.

When looking for a gantry crane, you should consider several factors, including but not limited to your required lifting capacity, lifting distance, hook coverage area, lifting frequency, working conditions, your budget, and some other safety concerns. After considering these issues, you will undoubtedly have a proper assessment of your material handling requirements. Alternatively, you can provide some basic information about your liting requirements and crane application conditions, and we will be happy to assist you in selecting the appropriate lifting equipment. Come to Yuantai Crane to find the best material handling solution for your personalized applications.

How to Operate Rail Mounted Gantry Crane

Cabin control is commonly used to handle large and heavy workloads. Crane operators should be given professional training in crane knowledge and safety regulations. To complete the lifting tasks, they may need to collaborate with staff on the ground.

Some time, the remote control is also an optional, which depends on your rail mounted gantry crane design.

cabin crane contol for rail gantry crane

cabin crane contol for rail gantry crane Joystick remote control for rail mounted gantry crane

Joystick remote control for rail mounted gantry craneOperators of rail mounted gantry cranes should never be careless or lax in the event of an accident, even if it is fatal. Furthermore, some safety devices, such as limit switches, overload limits, and anti-collision devices, can be installed on RMG cranes to ensure safe operation.

Get the Latest Rail Mounted Gantry Crane Price

We are a gantry crane manufacturer and supplier in China, and we will provide you with gantry crane factory prices. In addition to overhead and gantry cranes, we offer jib cranes, electric hoists, construction winches, and marine winches to meet your diverse needs. We can also customize the cranes to meet your specific requirements. Our gantry cranes are CE and ISO certified, and we maintain strict quality control. We guarantee to provide the best gantry crane service to customers, from crane design to manufacturing, packaging, and shipping, as well as installation, inspection, and maintenance. If you're worried about how much a rail mounted gantry crane will cost, contact us right away and we'll give you the best deal.

没有评论:

发表评论