An electromagnetic bridge crane is a type of double-girder bridge crane that is equipped with a detachable steel scrape magnetic chuck and a corresponding operating system for handling and lifting metal objects. The electromagnetic bridge crane has a lifting capacity of 5 to 32 tons, including the weight of the electromagnetic. A5 and A6 are the working classes of electromagnetic cranes. The magnetic retention time ranges from 10 to 30 minutes.

The following table shows the specific parameters of an electromagnetic bridge crane:

- Product Type of Bridge Crane: QC electromagnetic bridge crane

- Lifting Capacity of Bridge Crane:5~32t

- Span Length of Bridge Crane: 10.5~31.5m

- Working Class of Bridge Crane: A5, A6

- Ambient Temperature of Bridge Crane:-20~40℃

Components of electromagnetic bridge crane

Crane bridge, trolley, crane traveling mechanism, driver's cabin, electrical system, electromagnetic system, including steel scrape magnetic chuck, rectification control equipment, cable connectors, and other components comprise an electromagnetic bridge crane.

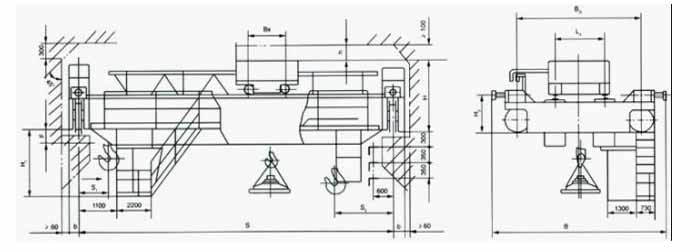

Electromagnetic bridge crane drawing

Electromagnetic bridge crane application

The electromagnetic bridge crane is a type of steel mill crane that can be used to handle and transport black metal products and materials both indoors and outdoors, such as ingots, pipe, structural steel, iron, scrap iron, steel, and others.

Advantages of electromagnetic bridge crane

- New style, compact structure, and delicate appearance

- Good usability and durability

- High loading capacity and working class

- High safety and dependability

- Light dead weight, low wheel load, and low noise

- Low power consumption and few faults

- Wide application and low cost

Features of electromagnetic bridge crane

- On materials. All of the crane's compression structural parts are composed of high-quality materials that comply with norms and standards, and an inspection record may be produced upon request.

- Concerning welding.Specialists will thoroughly verify and check the welding of steel structures, and inspection results can be produced upon request.

- Using the magnetic chuck. The magnetic chuck has a powerful magnetic field that can lift and carry a wide range of metal goods while also handling enormous volumes of metals at once.

- On motor. Top-of-the-line motors with good performance, Class F insulation, and IP54 protection are fitted.

- On the electric grid.All mechanisms can be controlled by a PLC, and any speed requirement can be met.

- Crane control of electromagnetic crane. You can choose from a cabin with a joystick panel, wireless control, or pendant control.

- Concerning painting.To keep the steel from rusting, three layers of paint are applied.

- On security. Various safety precautions are used to ensure crane and operation safety. Short circuit protection, lose phase protection, low-voltage protection, power failure protection, and over current protection are used to protect the mechanical system, while short circuit protection, lose phase protection, low-voltage protection, power failure protection, and over current protection are used to protect the electric system.

Crane magnetic

5 ton to 32 ton magnetic cranes is a metal-handling electric bridge crane with a magnet. Magnetic cranes and electromagnet cranes can be tailored to fit your needs. Now you can compare electromagnetic and magnetic cranes.

Yuantai Crane Hoist & Crane offers a variety of electromagnetic bridge cranes in various sizes to satisfy your specific needs.Yuantai Crane provides bespoke electromagnet cranes with customer crane electromagnets for handling steel scraps, billets, girders, slabs, wire (coiled bar), bundled rebar, round steel pipe, heavy rail, steel plate, and coiled steel, among other materials. To meet specific applications, the electromagnetic bridge crane are equipped with different types of electromagnets. Contact us to get your customized electromagnetic crane & magnets.

Round steel scrap lifting magnet

Round steel scrap lifting magnet Round lifting magnet for steel scrap handling

Round lifting magnet for steel scrap handling Permenant magnet

Permenant magnet Permenant magnet

Permenant magnet

Steel scrape magnetic chuck

Scrap iron lifting steel scrape magnetic chuck or lifting electromagnet, scrap electromagnet, scrap iron electromagnet, many titles, but the only purpose is to lift the scrap iron. In addition to the quality of the body, the density of the material must be considered. The larger the hoisting, the higher the density, and the lesser the hoisting, the lower the density. Many low-cost electromagnets cause the client to flicker. In reality, there is nothing wrong with the material; however, the magnet winding is insufficient, and there is a situation where electromagnets have poor waterproof performance and begin to fail after rain.

Electromagnetic sucker for raising steel pipes

Steel pipe lifting electromagnetic suckers are a type of electromagnet device that has a high frequency and high pressure load. To run for a long time without heat or resistance, it takes 24 hours. Quality necessitates excellence in appearance.

Magnetic chuck for excavator steel scrape

Excavator steel scraping magnetic chuck is also known as hook machine electromagnetic sucker, hook electromechanical magnet, and digger electromechanical magnet. It's a type of electromagnetic sucker that arose from a discarded electromagnet. It is easy to use and install on the excavator. Flexibility is a must. The generator consumes a lot of oil.

Automatic electromagnet

Automatic electromagnets enable continuous operation for 24 hours, suction must be strong and reliable, the appearance must be pleasing, and security must be maintained within the complete voltage range.

没有评论:

发表评论