Electric hoist in the process of running on the I-beam is prone to the problem is the object shaking, then how to solve the problem? Dongqi crane machine will answer you below questions:

The distance of the electric hoist on the end beam should not be too far. If the distance is too far, it can’t load the fixture in the middle. Do not allow the lifting load to run near the side of the end beam. Lifting the load Shocking will touch people and things or fall, which could lead to major accidents such as death or serious injury. If the load is shaking, the more powerful the shaking, the more difficult it is to run the hoist trolley, also it will more danger. In principle, do not shake the load horizontally. Therefore, please observe the following.

- do not pull down

- horizontal movement to make it slowly start

- do not lift the load quickly

When lifting and stopping the lateral movement of the chain hoist, even if the above operation is followed, the lifting load will be somewhat shaken. At this time, if the following operation, will be able to reduce the lifting load shaking.

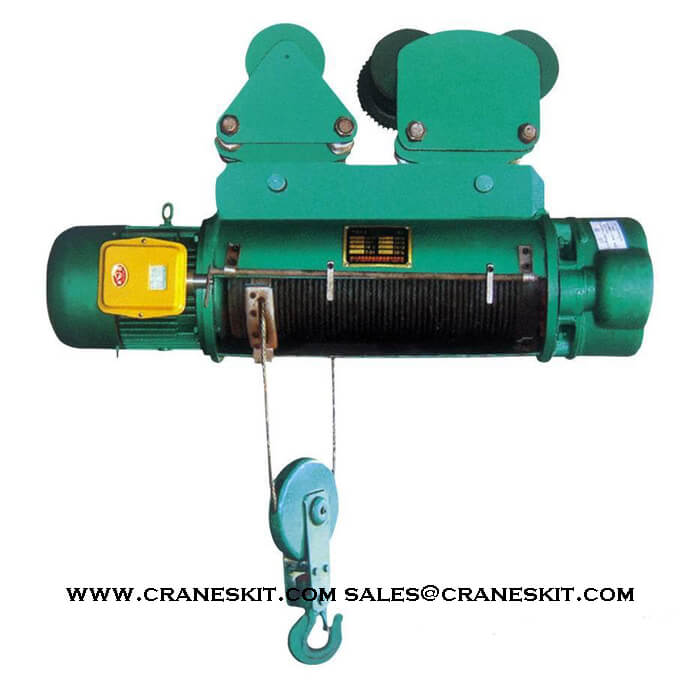

CD1 electric hoist need to pay attention to the six points

- CD1-type electric hoist often in the I-beam track back and forth, the track must be installed at both ends of the block to prevent misuse to make hoist derailment. It is advisable to have a height at both ends of the I-track orbit, a reliable resilient cushion or a baffle with a rubber block, and the I-beam track should not protrude outdoors. Extend the part to be equipped with rain protection device.

- I-beam track to meet the requirements of the grounding line. If the I-beam rail ground wire cross-sectional area is too small or no ground wire, when someone touches the hook, there is the risk of electric shock. Therefore, the I-beam rail grounding wire must be connected, the specifications are generally 4-5mm diameter bare copper or cross-section of not less than 25mm flat steel, and should be regularly patrol.

- The correct use of limiters and guide rope. The limiter has a limiting effect on the lift of the electric hoist to prevent the hook from rising too high against the reel or falling too fast to pull off the wire rope. The rope is mounted on the sleeve of the rope slot and moves axially with the sleeve to align the wire rope on the sleeve and collide with the stop plate on the lever , So that the hook automatically in the lift limit, to ensure the safe operation of electric hoist. Limiter, guide rope is an indispensable electric hoist security accessories, can effectively prevent the top bad guards and litter accidents.

- Wire rope refueling maintenance methods to be correct. The correct method of refueling is that when the rope is working, the oil (must use steel wire grease or thin oil, cannot use butter) to the reel or pulley to the rope on the subject of the vertex, so that it is naturally sucked into the rope.

- Adhere to the mobile mode of operation. Some of the units used to improve the operator working conditions, will be installed in the hoist on the control box moved to the wall fixed, the operator can sit in the chair "remote control command", at the same time, also increased the probability of the accident. Therefore, the control box to be installed in the electric hoist, the control line cannot be too long, so that operators in the horizontal operation with the gourd movement, so that both at any time to observe the operation of equipment, but also to avoid accidents.

- Strict implementation of regular maintenance system. In accordance with safety regulations, electric hoist and other lifting equipment to regular maintenance. In addition to regular maintenance of the gourd (including the replacement of Electrical components replacement), but also regular overhaul, wear parts must be replaced in time. Overhaul, to strictly follow the procedures for debugging, qualified before put into use.

没有评论:

发表评论